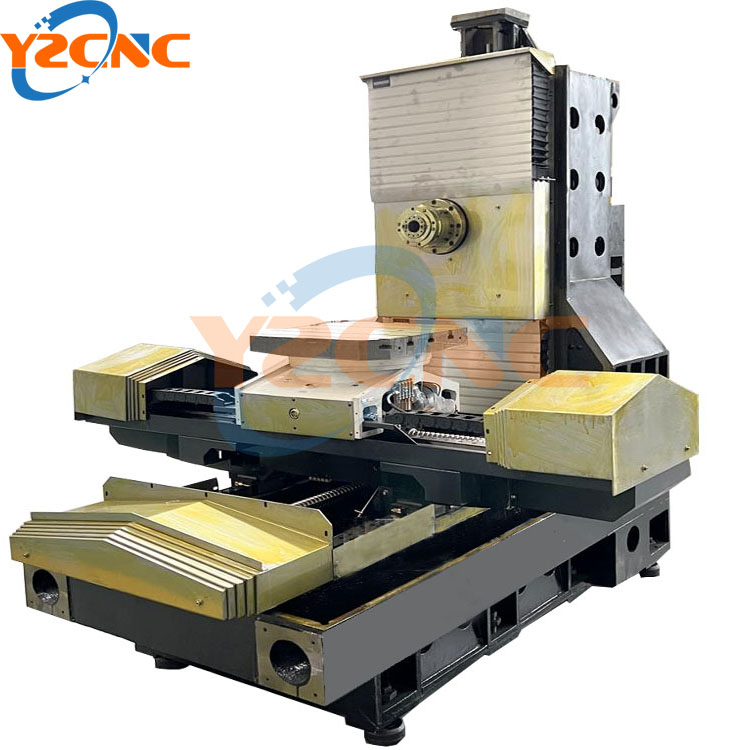

All CNC lathes and castings of vertical machining centers in our company have undergone natural aging treatment, and the precision of the machine tools is stable and good. From the aluminum alloy steel frame of the aerospace satellite to a small screw, any produced workpiece will generate stress, and the internal stress will be redistributed inside the workpiece over time to cause deformation of the workpiece. Once the workpiece is deformed, it will be damaged. The accuracy of use is affected, and the elimination of stress can solve this problem.

There are three main methods of aging treatment for machine tool castings. Natural aging/artificial aging

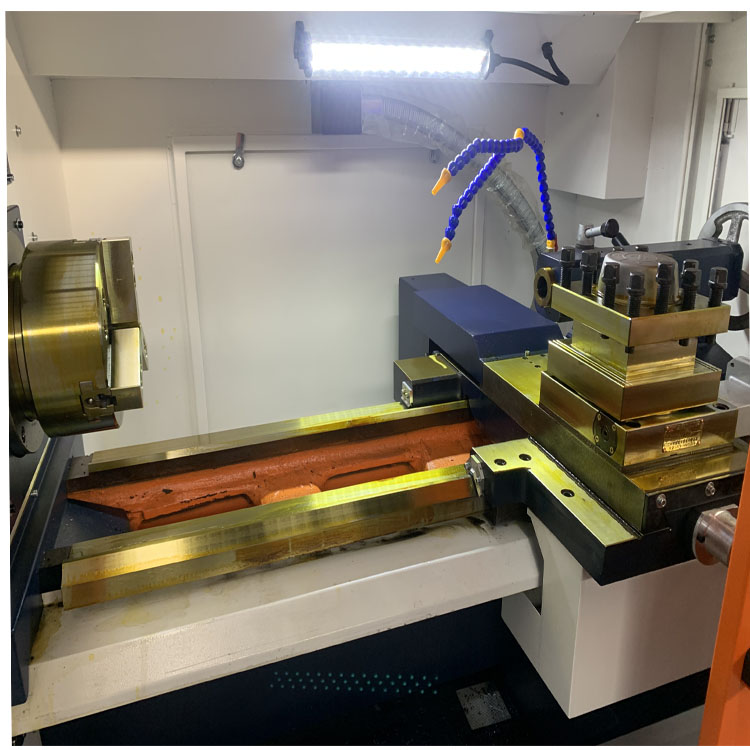

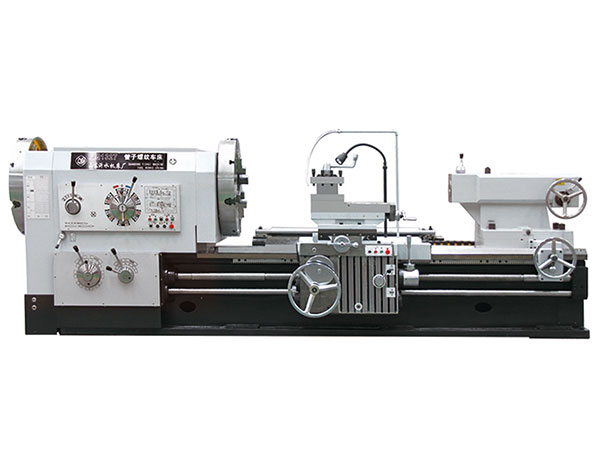

Lathe Machine Casting natural aging

Natural aging is placing the castings in the open air, relying on the power of nature, after More than 6 months to several years of wind, sun, rain, and seasonal temperature changes, the internal stress of the workpiece is naturally released, and the effect of stress relief is the most thorough.

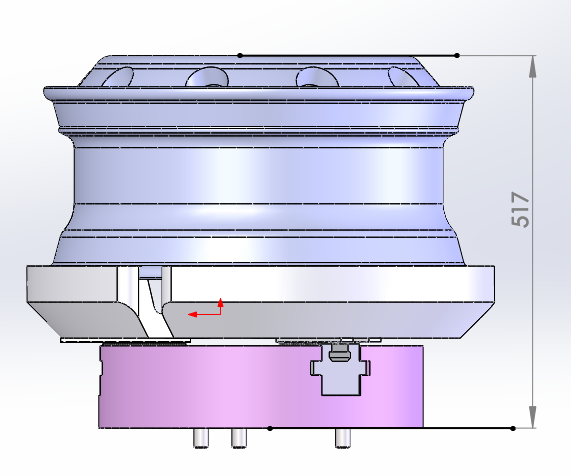

Artificial aging of machine tool castings

Usually, machine tool castings are subjected to vibration aging treatment, that is, the excitation force generated by the exciter is used by an external force to make the casting produce low-frequency resonance. The method of eliminating or homogenizing the residual stress is called time-to-failure vibration.

The vibration aging period is short, the efficiency is high, and the specific heat aging energy saving is 90% to 95%. Vibration aging can reduce or homogenize the residual stress of machine tool castings to improve dimensional stability, and can also strengthen metals to increase elastic modulus and improve the load-bearing and deformation resistance of machine tool castings.

After vibration aging treatment, the anti-static static load capacity of machine tool castings can be increased by 30%, and the anti-dynamic load capacity can be increased by ~300%. For aging treatment of machine tool castings, DC motor-type vibrators are generally used. Three issues should be paid attention to in the vibration aging treatment of machine tool castings. Dynamic stress is the exciting force, vibration frequency, and vibration time. It should be determined according to the material, quality, stiffness, shape, and support method of the machine tool castings. The vibration time of castings of one ton and below is 10-20min, the vibration time of castings of one ton and less than five tons is 20-30min, and the vibration time of castings of more than five tons is 30-35min.

static load capacity of machine tool castings can be increased by 30%, and the anti-dynamic load capacity can be increased by ~300%. For aging treatment of machine tool castings, DC motor-type vibrators are generally used. Three issues should be paid attention to in the vibration aging treatment of machine tool castings. Dynamic stress is the exciting force, vibration frequency, and vibration time. It should be determined according to the material, quality, stiffness, shape, and support method of the machine tool castings. The vibration time of castings of one ton and below is 10-20min, the vibration time of castings of one ton and less than five tons is 20-30min, and the vibration time of castings of more than five tons is 30-35min.

The support method of machine tool castings during artificial aging treatment is also particular. To ensure the effectiveness of aging treatment, beam castings adopt a 2-point support method, cylindrical castings adopt a four-point support method, and large-scale machine tool castings adopt a three-point support method. The support method is used for artificial aging treatment and multi-stage position aging treatment