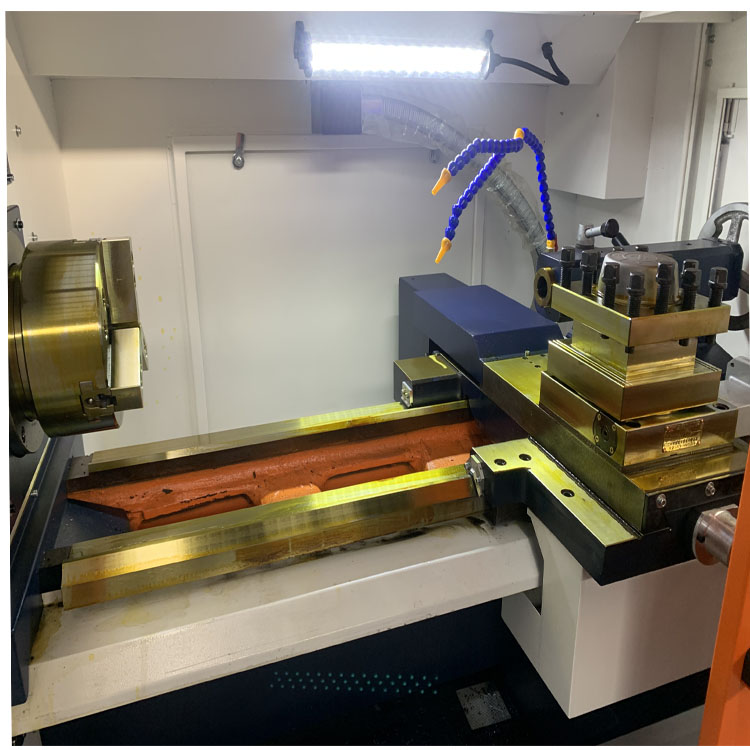

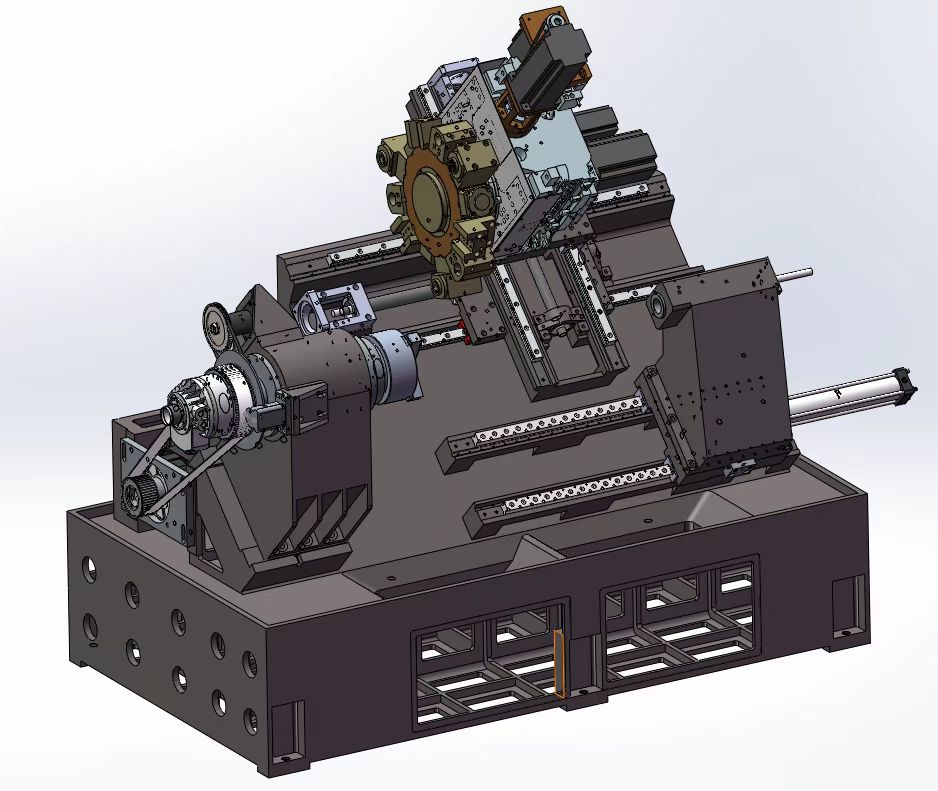

1. Slant bed cnc lathe layout. The supporting plate of the slant bed cnc lathe intersects obliquely with the ground plane, and there are many angles. Viewed from the side, the bed is in the form of a right triangle. When the width of the guide rail is the same, the X-direction supporting plate of the inclined bed is better than that of the flat bed cnc lathe. To be longer, you can arrange more to the mantissa.

1. Slant bed cnc lathe layout. The supporting plate of the slant bed cnc lathe intersects obliquely with the ground plane, and there are many angles. Viewed from the side, the bed is in the form of a right triangle. When the width of the guide rail is the same, the X-direction supporting plate of the inclined bed is better than that of the flat bed cnc lathe. To be longer, you can arrange more to the mantissa.

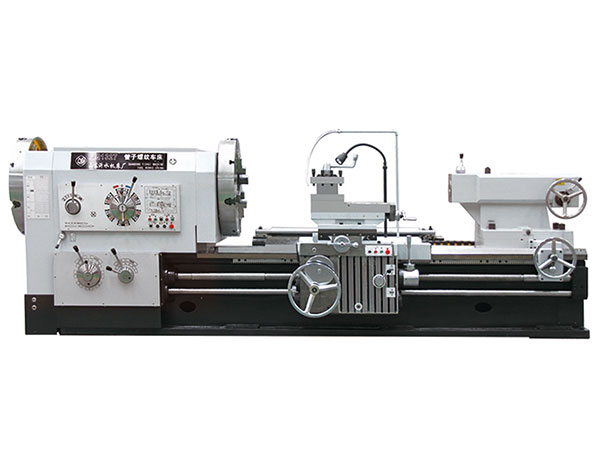

2. Slant bed cnc lathe Comparison of cutting rigidity. The tool of the Slant bed cnc lathe cuts downwards on the oblique upper direction of the workpiece, and the cutting force is consistent with the gravity direction of the workpiece, so the spindle runs relatively smoothly, which is not easy to cause cutting vibration, while the flat bed CNC lathe is proportional to the gravity of the workpiece during cutting. 90°, it is easy to cause vibration.

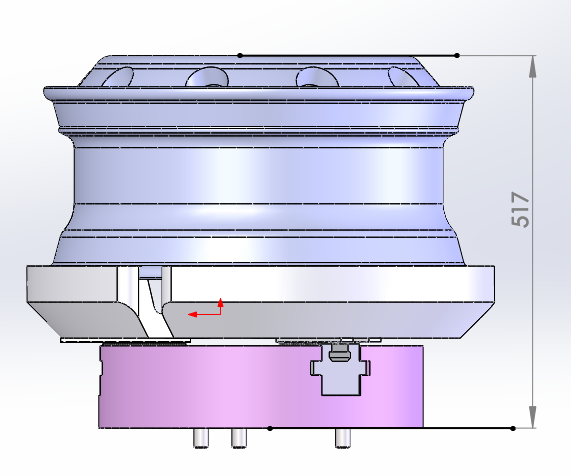

3. Slant bed cnc lathe Comparison of machining accuracy. The Slant bed cnc lathe can directly affect the clearance of the ball screw in the X direction, and gravity acts on the axial direction of the screw, so that the reverse clearance is almost zero during transmission, while the clearance of the X-direction screw of the flat bed cannot be directly eliminated, which makes the two There are differences in the repeated positioning accuracy between them, which in turn affects the machining accuracy.

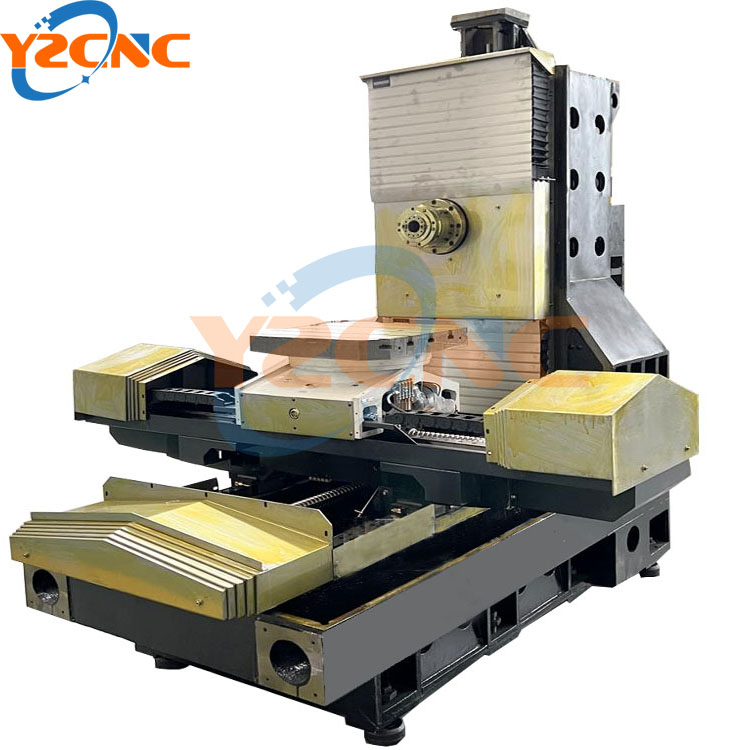

4. Slant bed cnc lathe Comparison of chip removal capabilities. The Slant bed cnc lathe is good for chip removal under the influence of gravity, it is not easy to cause tool entanglement and it is convenient to match with an automatic chip removal machine to increase processing efficiency, while the flatbed is difficult to achieve.