- VMC Series Vertical Machining Center

- VTC Series Vertical CNC Lathe Machine

- TCK Series Slant Bed CNC Lathe

- WRC Series Wheel Repair CNC Lathe

- QK Series Large Bore Pipe Thread Lathe

- CK Series Horizontal CNC Lathe Machine

- CK Series Heavy Duty CNC Lathe

- CA Series Universal Lathe

- Drilling and Milling Machine

- Sawing Machine

- Slotting Machine and Shape

- Radial Drilling Machine

GET A QUICK REQUESTS

The main types of vertical lathes are steering knuckle Vertical cnc lathe, Pulley Cnc lathe machine, Truck Brake Vertical CNC Lathe, Brake Drum Vertical Lathe, Brake Pad Vertical CNC Lathe, Engine Flywheel Vertical Lathe.

VTC800 Vertical Cnc Lathe Product introduction and usage

The Vertical cnc lathe machine is an automatic CNC machining vertical machine tool used to process the inner and outer cylindrical surfaces, conical surfaces, end faces, grooves, and chamfers of parts. It is especially suitable for various flanges, brake hubs, drums, and processing parts such as clutch pressure plates and flywheel housing.

The Vertical cnc lathe machine is an automatic CNC machining vertical machine tool used to process the inner and outer cylindrical surfaces, conical surfaces, end faces, grooves, and chamfers of parts. It is especially suitable for various flanges, brake hubs, drums, and processing parts such as clutch pressure plates and flywheel housing.

VTC800 Vertical Cnc Lathe Main structural features

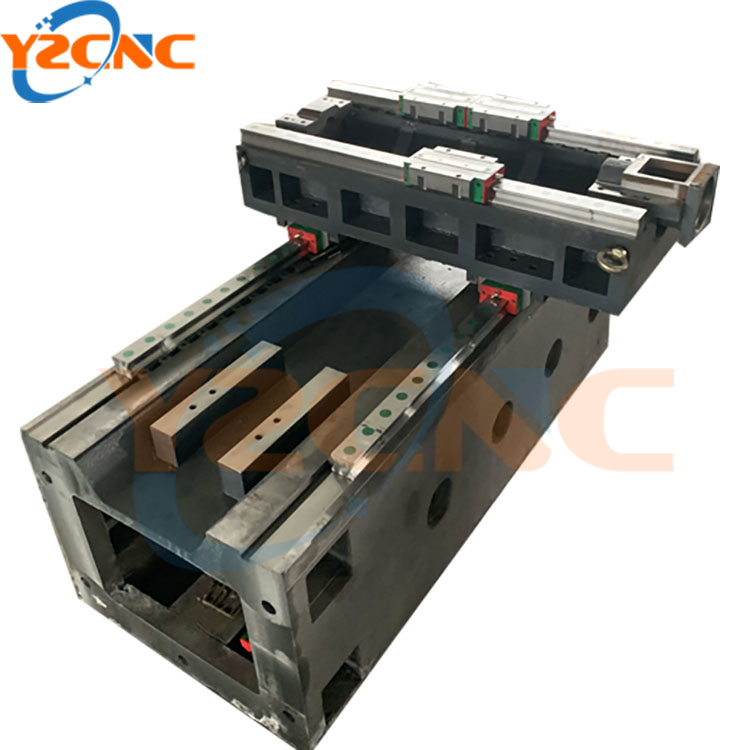

The vertical cnc lathe machine is a single-column vertical guide rail structure. The column, base, and sliding seat are all made of high-grade gray cast iron resin sand casting technology and have been subjected to aging treatment; reasonable structural design, perfect processing, and assembly technology ensure the long-term use of the machine tool stability and precision retention.

②Spindle of The Vertical cnc lathe machine is driven by a low-speed high-torque servo motor, which meets the needs of rough machining and finishing at the same time.

②Spindle of The Vertical cnc lathe machine is driven by a low-speed high-torque servo motor, which meets the needs of rough machining and finishing at the same time.

③Spindle of The Vertical cnc lathe machine is equipped with high-precision double-row cylindrical roller bearings, two-way thrust angular contact ball bearings, and double-row cylindrical roller bearings. This configuration structure has the largest bearing capacity, can withstand larger cutting force and feed force, has higher radial stiffness and axial stiffness, and has higher rotation accuracy.

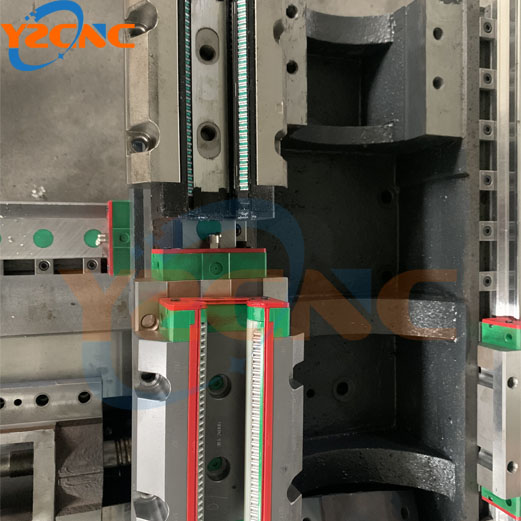

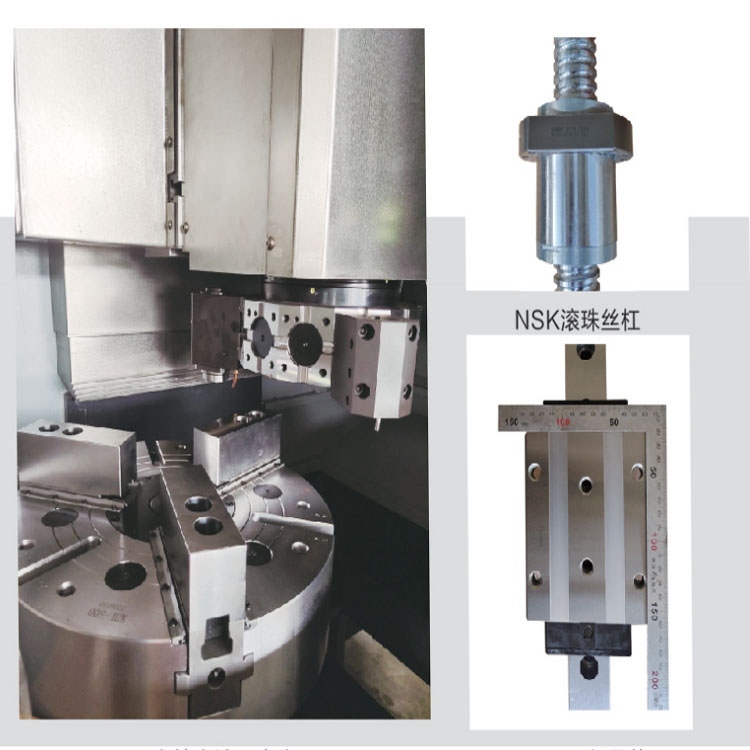

④X and Z-axis servo motors directly drive precision ball screw pairs through flexible couplings, which can minimize backlash and have high positioning accuracy. The Z-axis lift is equipped with a balancing counterweight, the structure is simple and reliable, and the failure rate is low.

The X and Z axes adopt domestic precision ball screw pairs and ball screw special bearings to meet the requirements of high rigidity and high precision cutting. The screw support adopts a pre-stretched structure, which greatly reduces the influence of thermal deformation on the accuracy of the machine tool during long-term operation.

⑤ The X and Z axes adopt an advanced centralized automatic lubrication device, which is automatically and intermittently lubricated at regular intervals, and the work is stable and reliable.

⑥The tool holder of the Vertical cnc lathe machine adopts the form of an electric tool holder or row tool, with accurate precision and high efficiency.

⑦Vertical cnc lathe machine can Optional KND, GSK, Siemens, Fanuc.

| Machine Tool Name | Vertical Cnc Lathe | |

| Model | VTC800 | |

| X Axis Travel | mm | 500mm |

| Z Axis Travel | mm | 650mm |

| Max.swing over bed | mm | 800mm |

| Max turning dia. | mm | 750mm |

| Spindle speed | rpm | 50~1000 |

| Spindle motor power | kw | 18.5,750pr |

| Spindle type | A2-11 | |

| Axis diameter of spindle | mm | 160 |

| Torsional | NM | 475 |

| Turret | 12 | |

| Front bearings | NN3032 | |

| Rear bearings | NN3026 | |

| Speed-down | 1:2.5 timing belt | |

| Clamping system | mm | ∮500mm Hydraulic Chuck |

| Ball screw accuracy | C3 | |

| Ball screw diameter x.z | X:φ40 Z:φ40 | |

| XZ axis rapid feed rate | m/min | 16 |

| Repeat positioning | mm | ±0.003 |

| Positioning | ±0.008 | |

| Coolant motor | w | 200 |

| Pump flow | cube | 4 |

| Cutting Fluid Tank volume | L | 200 |

| Machine Size | mm | 2200×2000×2900 |

| Weight | T | 9 |

Related Products