- VMC Series Vertical Machining Center

- VTC Series Vertical CNC Lathe Machine

- TCK Series Slant Bed CNC Lathe

- WRC Series Wheel Repair CNC Lathe

- QK Series Large Bore Pipe Thread Lathe

- CK Series Horizontal CNC Lathe Machine

- CK Series Heavy Duty CNC Lathe

- CA Series Universal Lathe

- Drilling and Milling Machine

- Sawing Machine

- Slotting Machine and Shape

- Radial Drilling Machine

GET A QUICK REQUESTS

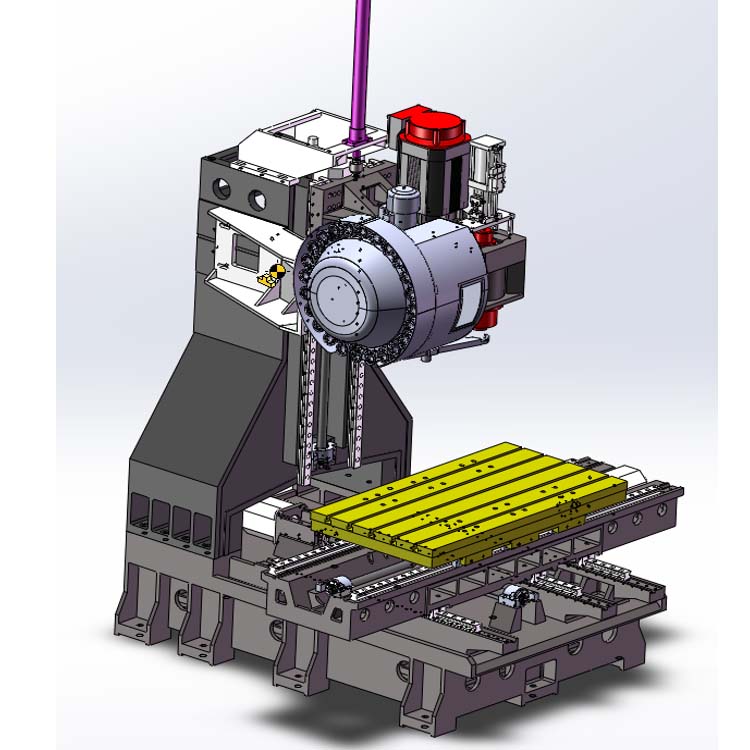

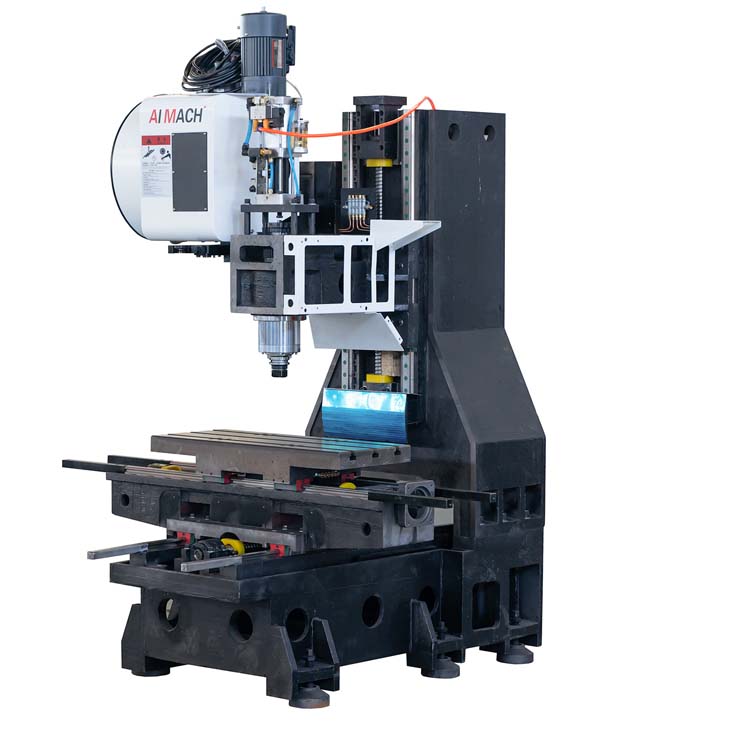

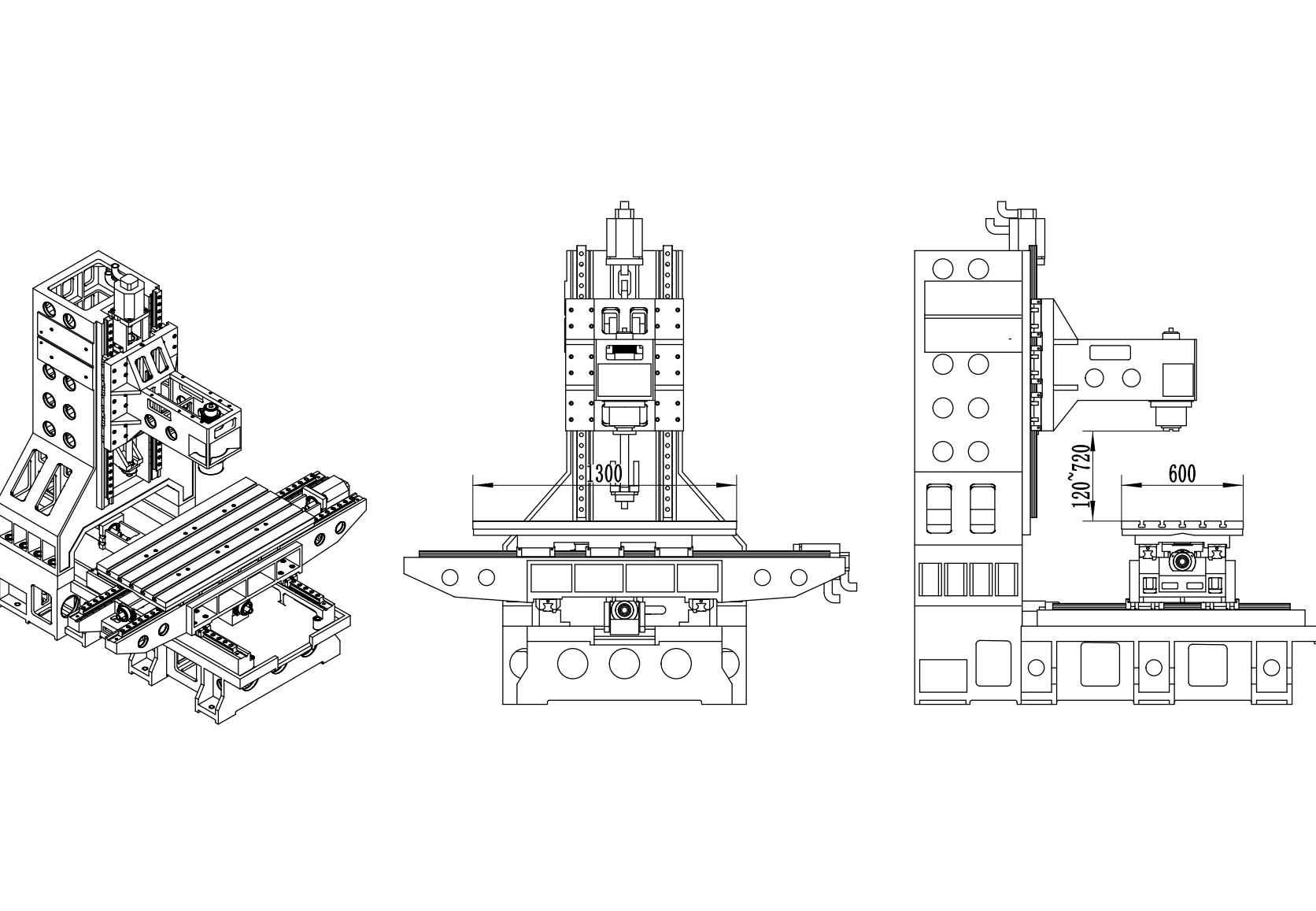

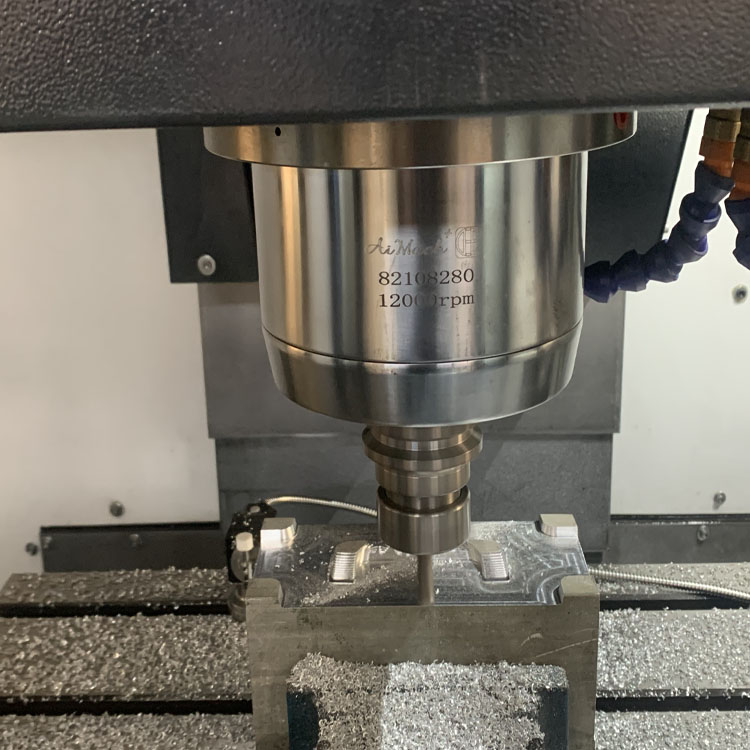

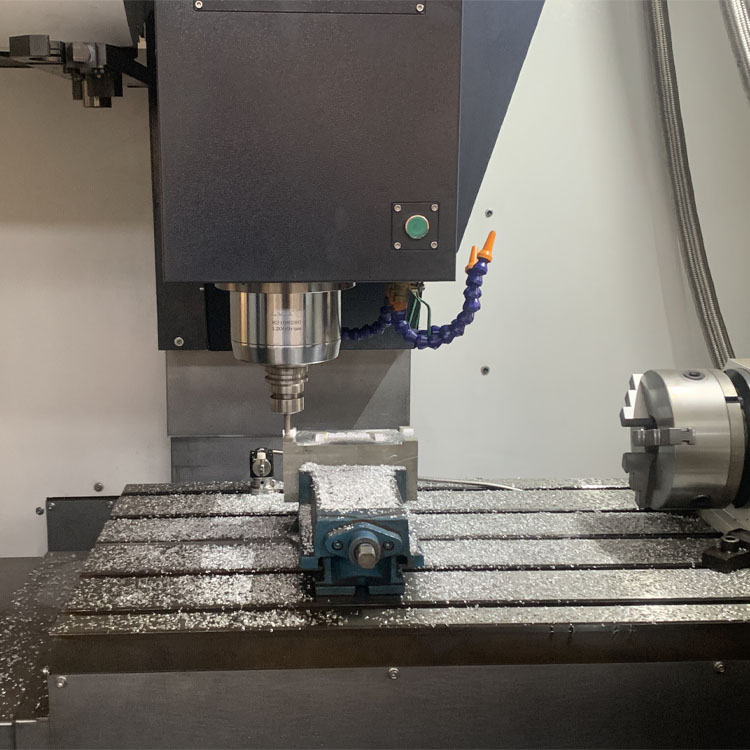

VMC1270 Vertical 5-Axis Cnc Machining center is made of high-grade cast iron with twice heat treatments and magnetic resonance. Natural aging relieves internal stress to ensure the lasting best rigidity and high precision. The bed base assembled with the long-span column design increases the contact area between the column and the base. A 3-axis machine tool assembled with square guide rails increases the processing strength and stock resistance significantly. The epoxy resin stick processing and artificial scraping grinding ensure precision and stability,

VMC1270 Vertical 5-Axis Cnc Machining center Standard accessories

VMC1270 Machine tool FANUC SYSTEM /SIEMENS/GSK218M/SYNTEC /Mitsubishi system

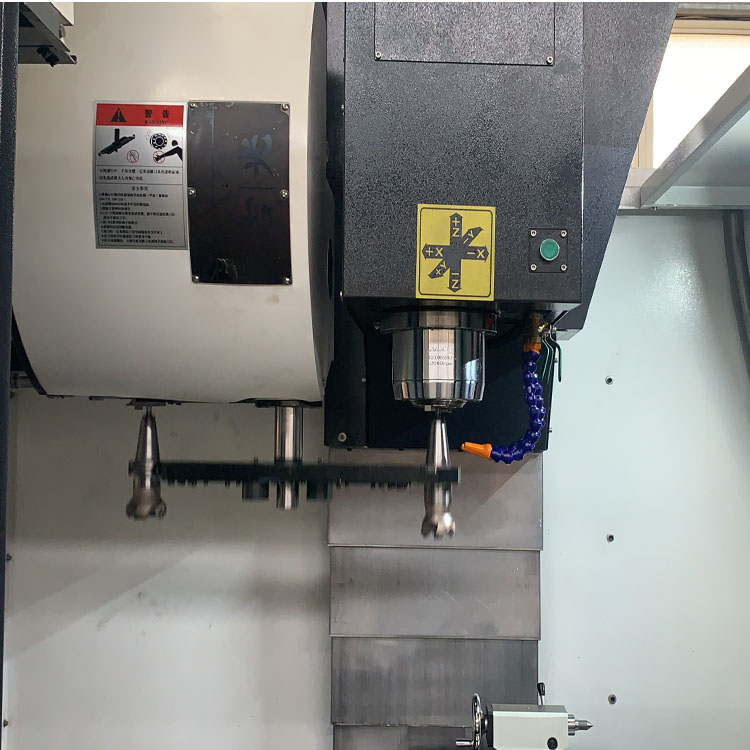

BT40/8000RPM Spindle or BT50/6000RPM Spindle

Spindle Oil cooler

Constant temperature device in the electrical box

Fully automatic lubrication system

Spindle oil cooling system

Cutting blow device

cutting cooling unit

Rigid tapping function

Leveling screw and footings

Operating instruction

Basic toolbox

Options

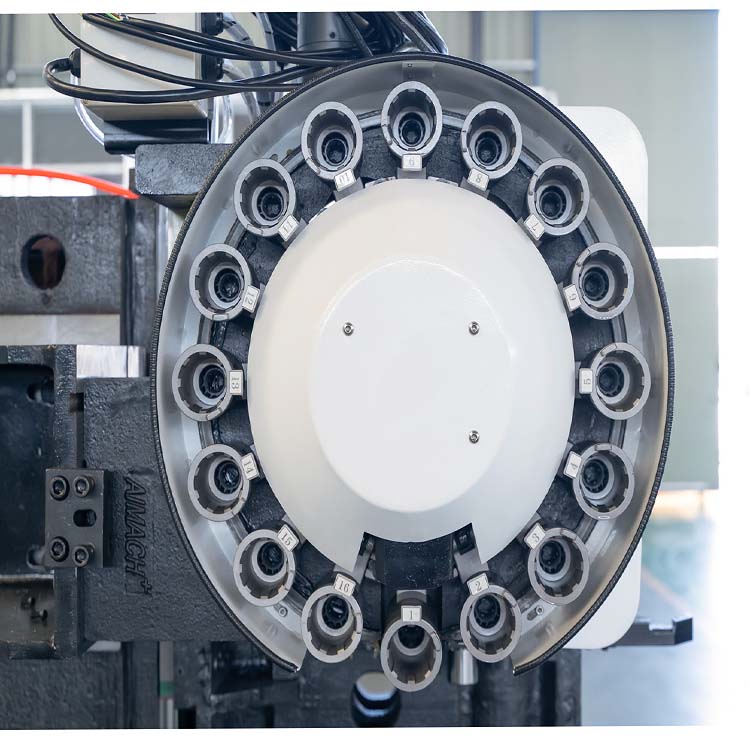

24/30/32 Disk knife library

Spindle center outlet system

Tool measuring system

VMC1270 Vertical 5-Axis Cnc Machining center Specification

| ITEM | UNIT | VMC1270 | ||

| Table | Size | MM | 1300 X700 | |

| Max load | KGS | 850 | ||

| T-Slot size | MM | 18 X 5 | ||

| Working area | X-axis | MM | 1200 | |

| Y-axis | MM | 700 | ||

| Z-axis | MM | 700 | ||

| Spindle nose to table | MM | 100-800 | ||

| Spindle center to z axis guide surface | MM | 750 | ||

| spindle | Spindle taper | BT40-150 | ||

| Spindle speed | RPM | 8000 | ||

| spindle motor power | KW | 11/15 | ||

| Feed | Fast feed | X | M/MIN | 24 |

| Y | M/MIN | 24 | ||

| Z | M/MIN | 20 | ||

| cutting speed | MM/MIN | 1-1000 | ||

| feed motor power | X | N | 22 | |

| Y | N | 22 | ||

| Z | N | 22 | ||

| Capacity | Types tool changers | Funnel type tool changer/Arm type tool changer ATC | ||

| Capacity of tools | 20/24 | |||

| Tool change time | S | 8/2.5 | ||

| Accuracy | Position Accuracy | MM | ±0.006 | |

| Repeatability | MM | 0.008 | ||

| Size | machine size | MM | 3500 X 2900 X 2800 | |

| Packing dimension | MM | |||

| weight | Kgs | 7000 | ||

How to choose a Machining center

1. CNC system There are many options for our CNC system

GSK218M KND Syntec (Chinese famous brand) GSK KND has a long warranty of 3 years

FANUC/ Mitsubishi /Siemens

2. Tool magazine selection

(funnel type tool magazine capacity 16 20 Arm type tool magazine capacity 24 tool magazines

Funnel tool magazine, low price, 24 arn type magazines, high-cost performance, fast tool change

3. Selection of spindle speed

Spindle speed There are 8000/10000/12000rpm. The main difference between the three specifications is that the selected spindle bearings are different.

8000 rpm uses 8.1 large steel ball bearings, and 12000 rpm uses 6.7 small steel ball bearings. The bearing capacity differs by 13% in the axial direction and 22% in the radial direction. It is obvious that the 8000 rpm spindle is more rigid than the 12000 spindles, and is more suitable for heavy steel parts. cutting. The bearing for 12000 rpm is the same as that for 1000 rpm. The bearing is a loose fit, so it is more suitable for high-speed cutting. It is suitable for processing soft materials such as aluminum alloy. The spindle speed is not as high as possible, it should be selected according to your actual processing needs.

4. 4-axis machine tools and 5-axis machine tools can be selected

Contact us to send drawings and we can help you choose the best machine for you

5. If you are an agent, you can customize the appearance (MOQ 3 sets)

6. coolant through spindle

7. Spindle oil cooling (when the rotation speed reaches a long time 5000 pm

Related Products