- VMC Series Vertical Machining Center

- VTC Series Vertical CNC Lathe Machine

- TCK Series Slant Bed CNC Lathe

- WRC Series Wheel Repair CNC Lathe

- QK Series Large Bore Pipe Thread Lathe

- CK Series Horizontal CNC Lathe Machine

- CK Series Heavy Duty CNC Lathe

- CA Series Universal Lathe

- Drilling and Milling Machine

- Sawing Machine

- Slotting Machine and Shape

- Radial Drilling Machine

GET A QUICK REQUESTS

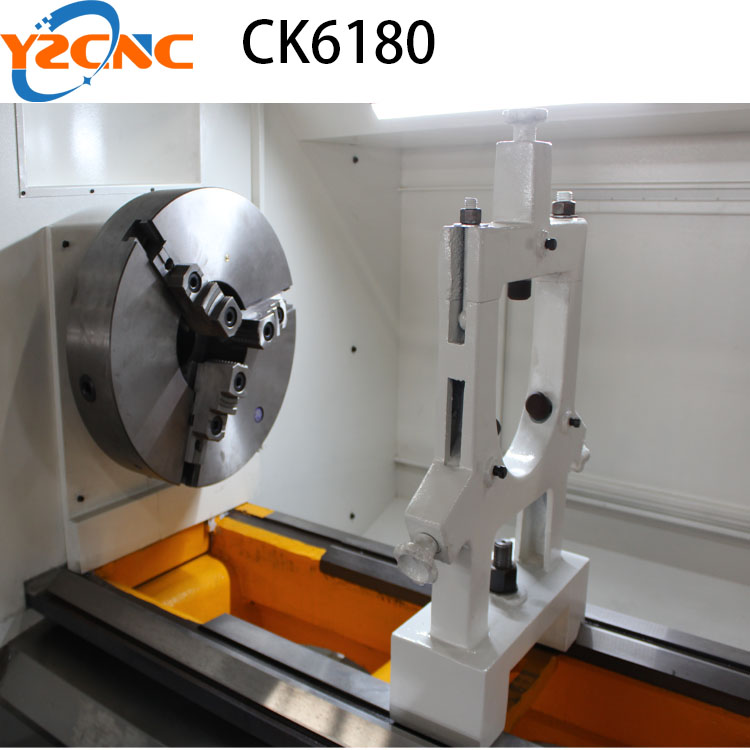

CK6180 Horizontal heavy duty cnc lathe the bed and foot of the bed are cast as a whole with resin sand, aging treatment, and the guide rail is  quenched by super audio frequency,The main sliding is free of plastic sticking technology, which eliminates crawling and improves accuracy.X/Z direction screw adopts three support structure,The base has high strength, and the widened pallet is suitable for heavy cutting.

quenched by super audio frequency,The main sliding is free of plastic sticking technology, which eliminates crawling and improves accuracy.X/Z direction screw adopts three support structure,The base has high strength, and the widened pallet is suitable for heavy cutting.

Horizontal Heavy Duty CNC Lathe Use:

The machine tool can automatically complete the processing of inner and outer cylindrical surfaces, conical surfaces, arc surfaces, end surfaces, etc., and can also realize the turning of male, British and various other forms of single and multi-thread threads.

Horizontal Heavy Duty CNC Lathe – Specification

| itm | unit | CK6163 | CK6180 | CK61100 | CK61125 | |

| Machining Range | Max. Swing over bed | MM | 630 | 800 | 1000 | 1250 |

| Max. Swing over cross slide | MM | 380 | 520 | 630 | 880 | |

| Max. center distance | MM | 1000/1500/2000/3000 | 1000/1500/2000/3000 | 1000/1500/2000/3000 | 1500/2000/3000 | |

| Spindle | Spindle bore | MM | 105 | 105 | 105/130 | 105/130 |

| Spindle speed steps | 4 | 4 | 4 | 4 | ||

| Chuck | MM | Manual 400 3-jaws chuck | Manual 400 3-jaws chuck | Manual 630 4-jaws chuck | Manual 630 4-jaws chuck | |

| Lathe bed | Bed width | MM | 550/600 | 550/600 | 600/700 | 700/755 |

| Feed | x/z fast feed | Mm/ min | 6000/8000 | 6000/8000 | 6000/8000 | 6000/8000 |

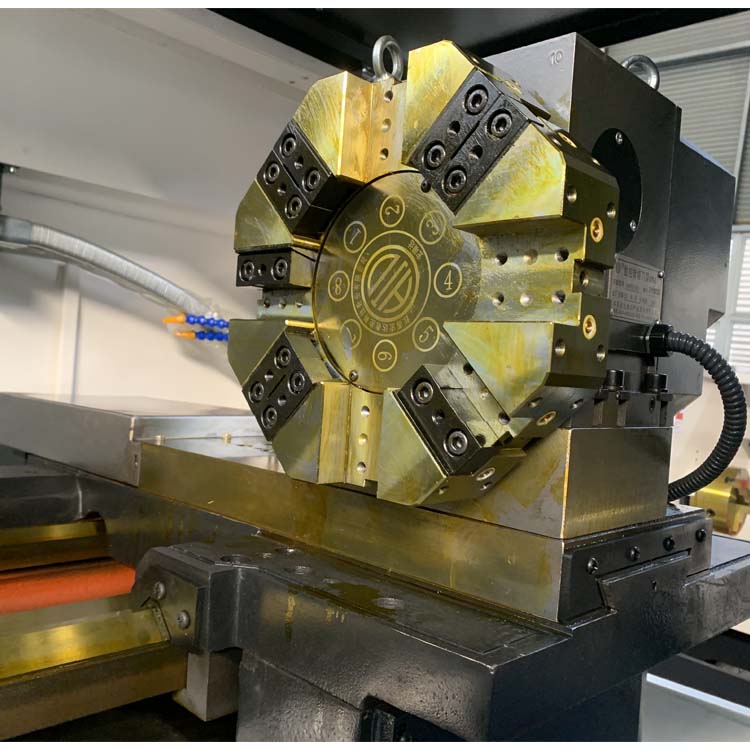

| Tool Turret | Number of tool turret | 4/6/8 | 4/6/8 | 4/6/8 | 4/6/8 | |

| Tool shank type | MM | 32*32 | 32*32 | 32*32 | 32*32 | |

| Working accuracy | Positioning accuracy | MM | X≤0.02 Z ≤0.025

| X≤0.02 Z ≤0.025 | X≤0.02 Z ≤0.025 | X≤0.02 Z ≤0.025 |

| Repeatability Positioning accuracy | MM | X≤0.015 Z ≤0.010 | X≤0.015 Z ≤0.010 | X≤0.015 Z ≤0.020 | X≤0.015 Z ≤0.020 | |

| roundness | MM | ≤0.01 | ≤0.01 | ≤0.015 | ≤0.015 | |

| Diameter uniformity | MM | ≤0.03(length 300mm) | ≤0.03length 300mm) | ≤0.03length 300mm) | ≤0.03(length 300mm) | |

| Flatness | MM | ≤0.02(Dia.300mm) | ≤0.02(Dia.300mm) | ≤0.02(Dia.300mm) | ≤0.02(Dia.300mm) | |

| Surface roughness | ≤Ra3.2um Steel parts | ≤Ra3.2umSteel parts | ≤Ra3.2umSteel parts | ≤Ra3.2umSteel parts | ||

| Tailstock | Dia.of tailstock sleeve | MM | 100 | 120 | 150 | 150 |

| Tailstock sleeve taper | MT6 | MT6 | MT6 | MT6 | ||

| Max. Tailstock sleeve travel | MM | 250 | 250 | 250 | 250 | |

| Motor | Spindle drive motor power | KW | 11 | 11 | 11/15 | 18/22 |

| Coolant pump power | KW | 120 | 120 | 120 | 120 | |

How to select heavy duty Lathe ?

Guide Rail Width Of machine tools

Select a heavy machine tool correctly, first of all, you must understand the weight and material of the workpiece you are processing, so as to select the appropriate width of the machine tool guide rail. The width of the machine tool guide rail affects the load bearing of the machine. The greater the width of the machine tool guide rail, the better the stability of the machine tool will be. CK6180 horizontal platform has 550mm and 600mm guide rail width.

Cnc System of machine tools

The choice of CNC system. There are many systems in the market now, which makes it difficult for us to choose which system is suitable for our own brand. In particular, many small brands have emerged. Summarize the top ten brands of CNC system.For customers to choose

TOP10 Cnc system Brand of machine tools

FANUC was founded in Japan in 1956, and its Chinese name is Fanuc (also translated into Frank). It is a powerful enterprise in the research, design, manufacturing and sales of CNC systems in the world today, with 4549 employees.

Siemens CNC system From Germany SINUMERIK has developed for many generations, mainly SINUMERIK3/8/810/820/850/880/805/802/840 series. Currently, 802, 810, 840, etc. are widely used

GSK Cnc system is the largest brand in China,Now the technology is mature, international G code, cost-effective, stable system quality, and three-year after-sales support

KND The CNC system is mainly based on KND0, KND1, KND10, KND100, KND1000 and K2000 series, of which K2000Ci is the bus system; Stepper drives include BD3H-C and BD3D-C, servo drives include SD200, SD300, SD310 (with bus system), servo spindle drives include ZD200, ZD210 (with bus system), and various series of servo motors and servo spindle motors, which meet the needs of various single-axis control machinery, CNC turning and milling and machining centers in the machine tool industry, and provide a full range of choices for different users

Syntec system is Taiwan’s new generation technology (the main production milling machine/lathe controller), Suzhou Huaxin CNC is the total sales in the mainland. Our system is applicable to 3/4/5/and other multi-axis machining centers, turn-milling compound machines, engraving and milling machines, special machines, grinders, CNC milling machines, etc.

Mitsubishi CNC system consists of NC hardware and NC software. The hardware of the numerical control system is composed of numerical control device, input/output device, drive device and machine tool electrical logic control device

FAGOR from Spain FAGOR

Turret tool of machine tools

4-station electric turret ,6/8-station electric turret , 8/10-station hydraulic Chuck

Chuck of machine tools

hydraulic Chuck : Hydraulic solid chuck Hydraulic hollow chuck, Have 3 jaw chuck,4 jaw chuck.

Related Products