- VMC Series Vertical Machining Center

- VTC Series Vertical CNC Lathe Machine

- TCK Series Slant Bed CNC Lathe

- WRC Series Wheel Repair CNC Lathe

- QK Series Large Bore Pipe Thread Lathe

- CK Series Horizontal CNC Lathe Machine

- CK Series Heavy Duty CNC Lathe

- CA Series Universal Lathe

- Drilling and Milling Machine

- Sawing Machine

- Slotting Machine and Shape

- Radial Drilling Machine

GET A QUICK REQUESTS

Advantages of Cnc Turning Lathe

Multi-station turrets can be installed on inclined-bed Cnc Turning Lathe. Under the same guideway width layout, the X-direction pallets of inclined-bed CNC lathes are larger, and more tool positions can be arranged for multi-sequence processing.

The inclined bed lathe has inherent higher precision and stronger cutting rigidity. The cross-sectional area of the inclined bed is larger than that of the flat bed CNC lathe of the same specification, the bending resistance and torque resistance are stronger, and the cutting force and the direction of gravity are the same. Therefore, the spindle runs relatively smoothly, and the layout of the CNC lathe with an inclined bed allows gravity to directly act on the axial direction of the lead screw, so that the backlash during transmission is almost zero, and it is not easy cause cutting vibration. The x-direction lead screw of the flat bed CNC lathe is not affected by gravity, and its cutting force is 90 degrees from the direction of the workpiece gravity, and the gap cannot be directly eliminated, which is easy to cause vibration.

The inclined bed CNC lathe is more convenient to discharge iron chips. Under the action of gravity, the inclined bed lathe is not prone to tool winding. At the same time, with the central screw and guide rail protection sheet metal, it can effectively avoid the accumulation of iron filings on the machine tool. The inclined bed lathe is easier to add to the automated production line. The servo-independent spindle of the CNC lathe with an inclined bed can be positioned and locked. Higher revs.

Configuration Introduction Of Cnc Turning Lathe

Bed Inclination 30 Degree Or 45 Degrees, 30 degrees Can add Driven Turret Tool Y-Axis. 45 Degrees can’t be with the Y-axis.

Turret :Electric turret 6/8 nos ,Hydrualic Servo Turret 8/12nos, Driven Turret Tool BMT45 BMT55

Chuck: Hydraulic Chuck 6 inch or 8 inch

Cnc Controller:GSK988TA /Siemens808/Siemens828/Fanuc/Syntec

Tailstock:Hydraulic

Option: Lathe Machine – Wireless Probing And Automatic Tool Presetter

Specification of Cnc Turning Lathe

| ITM | UNIT | TCK42(30 degree) Y-AXIS TCK42 (45degree) without Y AXIS | TCK550 (30 degrees) Y AXIS | ||

| Work Range | Max. swing dia. over bed | mm | 420 | 560 | |

| Max. swing dia. over slide | Mm | 195 | 360 | ||

| Max. cutting dia. Of disc type parts | mm | 420 | 550 | ||

| Max. cutting dia. Of axle type parts | mm | 195 | 360 | ||

| Distance between centers | mm | 500/1000/1500 | 500/1000/1500 | ||

| X/Z/Y Axis | X axis travel | mm | 240 | 320 | |

| Z axis travel | mm | 550/1050/1550 | 550/1050/1550 | ||

| Y axis | mm | ±35 | ±45 | ||

| X Z Fast feed | mm | 12000 | 12000 | ||

| Spindle | Spindle bore | mm | 56 | 66(A2-6)/86(A2-8) | |

| Max through hole bar diameter | mm | 40 | 50(A2-6)/75(A2-8) | ||

| spindle nose type | A2-5 | A2-6/A2-8 | |||

| spindle speed | rpm | 4000 | 3000 | ||

| Main motor power (C AXIS) | kw | 5.5KW Servo | 7.5KW Servo | ||

| accuracy | X Z axis positioning accuracy | mm | 0.012 | 0.012 | |

| X Z repeatability | mm | 0.003 | 0.003 | ||

| Diameter uniformity | mm | 0.03/300 | 0.03/300 | ||

| Flatness | mm | 0.03/300 | 0.03/300 | ||

| Number Turret | 12 servo power turret | 12 servo power turret | |||

| power turret | turret type | BMT40 Y-AXIS

| BT45/BT55 Y AXIS | ||

| Outer diameter Shank diameter | 20X20 | 20X20/25X25 | |||

| Inner shank diameter | 25 | 32 | |||

| Driven tooling | End face driven tool | ER20/3000RPM | ER25/3000RPM | ||

| Side face driven tool | ER20/3000RPM | ER25/3000RPM | |||

| Chuck | mm | Hydraulic Chuck(8inch) | Hydraulic Chuck 10 inch | ||

| Machine size | mm | 2500/3000/3500x1800X1800 | 2700/3200/3700X2100X1900 | ||

| 3.2T/3.7/4.2 | 3.8/4.3/4.8 | ||||

Accuracy -Turning Lathe

The CNC turning Center machine can execute exact measurements and eliminate human mistakes using CAD or CAM files. Experts can deliver incredibly high accuracy using cutting-edge machinery, whether for the production of prototypes or the completion of the entire production cycle. Every cut is precise since the machine being used is programmed. In other words, the final piece in the production run is identical to the first piece.

Flexibility-Turning Lathe

Cnc Turning Lathe comes in various sizes to accommodate your applications’ flexibility. The adjustment is rather easy because this machine’s tasks are preprogrammed. The operator can finish your component by making the necessary programming adjustments to your CAM program or even build something entirely different. Therefore, you can rely on the same precision CNC machining Parts services company if you need many unique parts.

Faster Results-Turning Lathe

There is a lower chance of error when tasks specified by programming are carried out on a Metal Cnc lathe machine or Cnc turning center. As a result, this machine can finish production more quickly without sacrificing the final output quality. Finally, you can receive the necessary components faster than with other options.

Lubrication-Turning Lathe

Lathe Using timing and quantitative centralized oil supply lubrication points can be fully lubricated

Ball screw-Turning Lathe

Lathe Using precision class heavy-duty ball screws with compact structure and high precision can effectively remove creeping phenomenon and ensure good dynamic, character, stability, accuracy maintenance, and reliability.

Heavy-duty casting-Turning Lathe

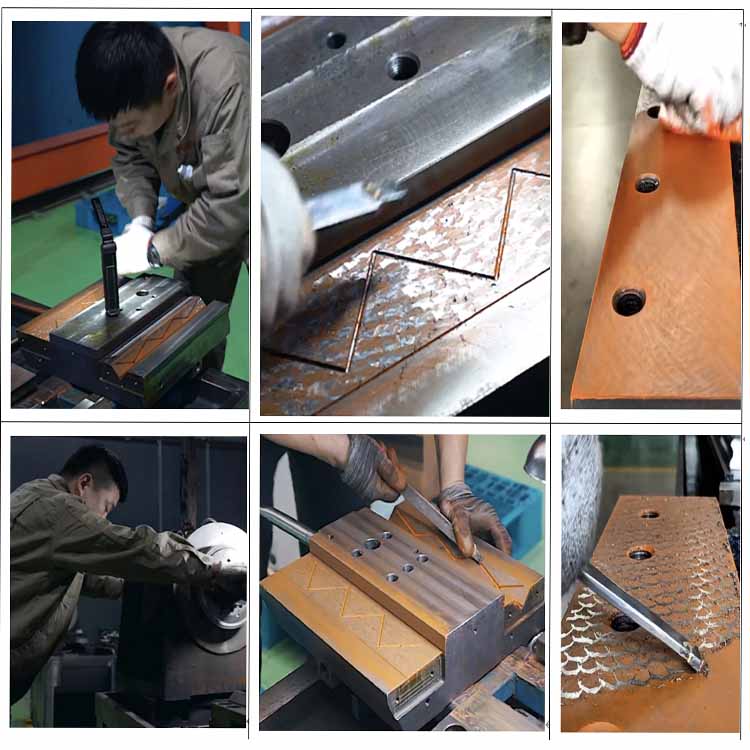

All castings are made of high-strength best quality casting iron with the best resin sand molding.

The castings must be shaped by twice aging treatments, it ensures the casting has the best stability and high strength. The process the guarantees high precision

How to ensure the quality of CNC machine tools

Quality Assurance: We strictly implement CE quality standards and have received CE certification. This means our production lines feature advanced technologies that give manufacturing precision and accuracy. With sophisticated measuring and testing equipment in-house, we check all incoming materials and parts to meet your specifications. That’s why we are outstanding among the rapid prototyping companies in China. Learn more about our quality control system.

TCK550 Cnc Turning Lathe Quality inspection before shipment

Measurement and calibration with Renishaw laser interferometer.

Related Products