CK6180 Cnc Lathe

CK6180 Cnc Lathe Standard

1.GSK980TDi Cnc system

2. Manual Three/Four Chuck

3. Manual tailstock

4. Automatic lubrication

5. working lamp

6. CK6180 Cnc Lathe CE /SGS certification

7. Voltage: As per customers’ requirement (380V/400V/220V)

8. Color: As customers’ requirement

9. Brand Name: YZCNC

CK6180 Cnc lathe Optional Configuration

1.Cnc controller :Siemens808/FANUC/SYNTEC/KND

2. Chuck: Hydraulic/Pneumatic Chuck

3.Tailstock:Hydraulic/pneumatic

4. Automatic Oil bath feeder

- VMC Series Vertical Machining Center

- VTC Series Vertical CNC Lathe Machine

- TCK Series Slant Bed CNC Lathe

- WRC Series Wheel Repair CNC Lathe

- QK Series Large Bore Pipe Thread Lathe

- CK Series Horizontal CNC Lathe Machine

- CK Series Heavy Duty CNC Lathe

- CA Series Universal Lathe

- Drilling and Milling Machine

- Sawing Machine

- Slotting Machine and Shape

- Radial Drilling Machine

GET A QUICK REQUESTS

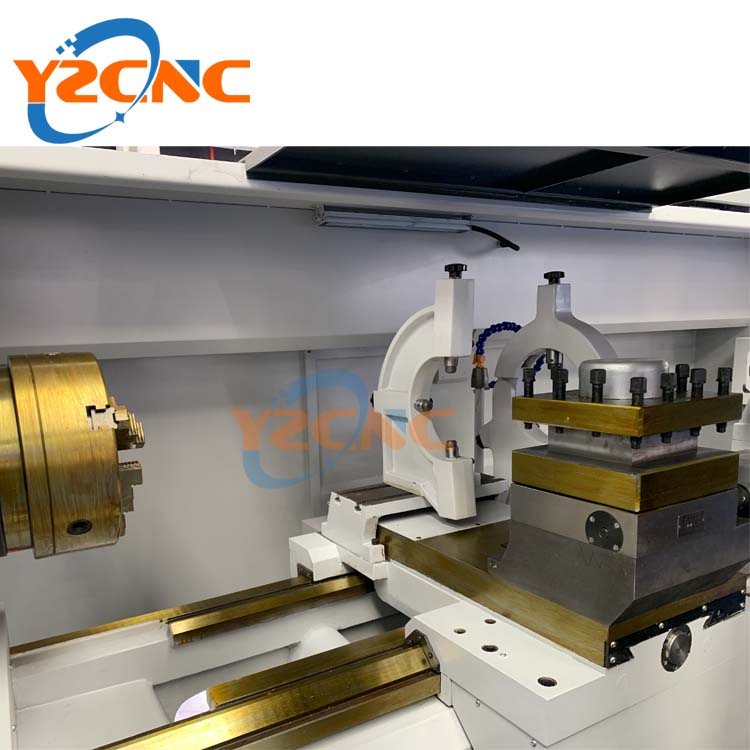

CK6180 CNC lathe also known as CAK6180 cnc lathe is a high-precision and high-efficiency machine tool that is widely used in the manufacturing industry. It is specifically designed for the processing of large and medium-sized parts with high precision requirements. This machine tool is equipped with a numerical control system, which can realize automatic control of the entire machining process, thereby improving the machining accuracy and efficiency of the workpiece.

CK6180 CNC lathe also known as CAK6180 cnc lathe is a high-precision and high-efficiency machine tool that is widely used in the manufacturing industry. It is specifically designed for the processing of large and medium-sized parts with high precision requirements. This machine tool is equipped with a numerical control system, which can realize automatic control of the entire machining process, thereby improving the machining accuracy and efficiency of the workpiece.

The main purpose of the CK6180 CNC lathe machine is to perform turning, drilling, and milling operations on workpieces made of various materials such as steel, aluminum, copper, and plastics. It can be used in industries such as aerospace, automotive, medical, and general engineering, and is suitable for the processing of shafts, disks, sleeves, and other complex parts. The following are some of the features of the CK6180 CNC lathe:

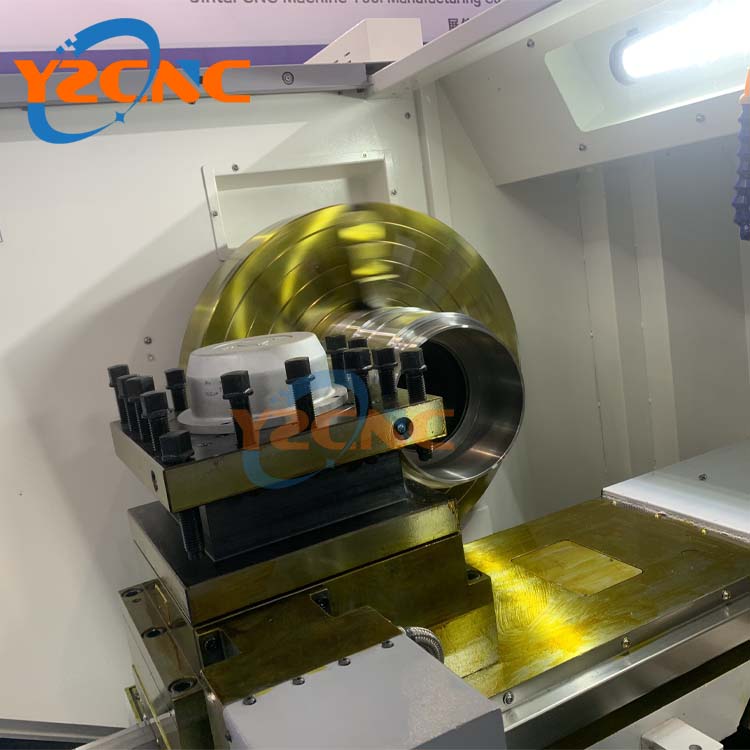

High-precision machining: The CNC system of the CK6180 Horizontal CNC lathe can accurately control the movement of the cutting tool, which ensures the high precision of the machining process. The lathe is equipped with high-precision ball screws and linear guides, which ensures the accuracy of the movement of the cutting tool and the workpiece.

High efficiency: The use of CNC technology ensures that the CK6180 heavy-duty CNC lathe can perform complex machining operations with high efficiency. The automatic tool changer, the high-speed spindle, and the fast feed rate of the machine can significantly reduce the machining time and improve production efficiency.

Easy operation: CK6180 CNC lathe has a user-friendly interface, which makes it easy to operate even for inexperienced operators. The machine is equipped with a touch screen and a keyboard, which allows the operator to input the machining parameters easily. The CNC system can automatically generate the machining program, which greatly reduces the programming workload.

Versatility: CK6180 CNC lathe can be used to machine various types of workpieces, including cylindrical, conical, and spherical parts. The lathe can also perform drilling, milling, and tapping operations, which greatly expands the range of applications.

Safety features: CK6180 CNC lathe is equipped with various safety features to protect the operator and the machine. The machine has an automatic alarm system that detects abnormalities in the machining process and stops the machine in case of an emergency.

The CK6180 CNC lathe is a versatile and efficient machine tool that can perform complex machining operations with high precision. The use of CNC technology has greatly improved machining efficiency and accuracy, and the user-friendly interface makes it easy to operate. With its wide range of applications, the CK6180 CNC lathe has become an indispensable tool in the manufacturing industry.

CK6180 Cnc Lathe Specification

| itm | unit | CK6161D | CK6166D | CK6180D | |

| Machining Range | Max. Swing over bed | MM | 610 | 660 | 800 |

| Max. Swing over cross slide | MM | 370 | 400 | 540 | |

| Max. Z axis Travel | MM | 750/1000/1500/2000/3000 | 750/1000/1500/2000/3000 | 750/1000/1500/2000/3000 | |

| Max. Z axis Travel | MM | 320 | 340 | 410 | |

| Spindle | Spindle bore | MM | 52/80/105 | 52/80/105 | 52/80/105 |

| Spindle nose | ISO (GB) D8 | ISO (GB) D8 | ISO (GB) D8 | ||

| Spindle speed range | RPM | 162-1500 /66-500/21-150 or 50-1800 | |||

| Spindle speed steps | independent spindle or 3 steps | ||||

| Chuck | MM | Manual 3 jaw 250 | Manual 3 jaw 250 | Manual 3 jaw 250 | |

| Lathe bed | Bed width | MM | 400 | 400 | 400 |

| Feed | x/z fast feed | Mm/ min | 5000/10000 | 5000/10000 | 5000/10000 |

| x/z cutting travel speed | Mm/ min | 1-6000 | 1-6000 | 1-6000 | |

| Tool Turret | Number of tool turret | 4/6/8 | 4/6/8 | 4/6/8 | |

| Tool shank type | MM | 25*25 | 25*25 | 25*25 | |

| Working accuracy | Positioning accuracy | MM | X≤0.010 Z ≤0.015 | X≤0.010 Z ≤0.015 | X≤0.010 Z ≤0.015 |

| Repeatability Positioning accuracy | MM | X≤0.0075 Z ≤0.010 | X≤0.0075 Z ≤0.010 | X≤0.0075 Z ≤0.010 | |

| Min. unit set | MM | 0.001 | 0.001 | 0.001 | |

| roundness | MM | ≤0.007 | ≤0.007 | ≤0.007 | |

| Diameter uniformity | MM | ≤0.03 L300 | ≤0.03L:300 | ≤0.03L:300 | |

| Flatness | MM | ≤0.02Dia.300 | ≤0.02Dia.300 | ≤0.02Dia.300 | |

| roughness | Ra1.6um | Ra1.6um | Ra1.6um | ||

| Tailstock | Dia. of tailstock sleeve | MM | 75 | 75 | 75 |

| Tailstock sleeve taper | MT5 | MT5 | MT5 | ||

| Max. Tailstock sleeve travel | MM | 150 | 150 | 150 | |

| Motor | Spindle drive motor power | KW | 7.5 | 7.5 | 7.5 |

| Coolant pump power | W | 120 | 120 | 120 | |

| size | L W H | MM | 750mm 2550×1550×1900 mm 1000mm 2750×1550×1900 mm 1500mm 3250×1550×1900 mm 2000mm3700×1550×1900 mm 3000mm4710×1550×1900 mm | ||

| weight | KGS | 750mm NW 2120/ GW 2820 1000mm NW 2240/ GW 3000 1500mm NW2350/ GW 3200 2000mm NW 2740/ GW 3400 3000mm NW 3600/ GW 4200 | |||

Related Products