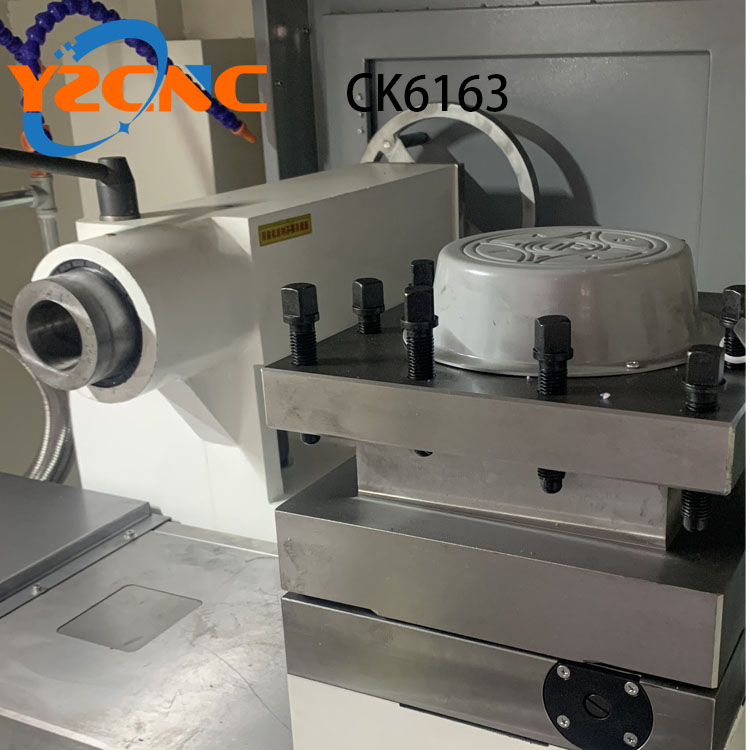

CK6163 Cnc Lathe Machine

CK6163 Cnc Lathe Machine is universal standard automatic machining equipment for metal processing ,capable of semi-finish machining and finish machining of machinery components and parts ,with the main characters such as reliable strucyure and easy operating .

- VMC Series Vertical Machining Center

- VTC Series Vertical CNC Lathe Machine

- TCK Series Slant Bed CNC Lathe

- WRC Series Wheel Repair CNC Lathe

- QK Series Large Bore Pipe Thread Lathe

- CK Series Horizontal CNC Lathe Machine

- CK Series Heavy Duty CNC Lathe

- CA Series Universal Lathe

- Drilling and Milling Machine

- Sawing Machine

- Slotting Machine and Shape

- Radial Drilling Machine

GET A QUICK REQUESTS

CK6163 Horizontal Cnc Lathe Machine has a heavy-duty cnc lathe machine and a light flat cnc lathe machine. Different rail width have 550mm and 400mm

Choose the lathe machine that suits you according to the weight of the workpiece.

CK6163 Cnc Lathe Machine Main Features

1. The bed and foot of the bed are cast as a whole with resin sand, and aging treatment and the guide rail is quenched by super audio frequency.

2. The main sliding is free of plastic sticking technology, which eliminates crawling and improves accuracy.

3. X/Z direction screw adopts three support structure

4. The base has high strength, and the widened pallet is suitable for heavy cutting.

CK6163 Cnc Lathe Machine Use

The Horizontal metal cnc lathe CK6163 can automatically complete the processing of inner and outer cylindrical surfaces, conical surfaces, arc surfaces, end surfaces, etc., and can also realize the turning of male, British, and various other forms of single and multi-thread threads.

CK6163 Cnc Lathe Machine Standard Configuration

GSK980TB3i

3 jaws manual chuck or 4 jaws chuck

4-station electric turret

manual tailstock

CK6163 Cnc Lathe Machine Specification

| itm | unit | CK6163 | CK6180 | CK61100 | |

| Machining Range | Max. Swing over bed | MM | 630 | 800 | 1000 |

| Max. Swing over cross slide M380520630Max | MM | 380 | 520 | 630 | |

| Max. center distance | MM | 1000/1500/2000/3000 | 1000/1500/2000/3000 | 1000/1500/2000/3000 | |

| Spindle | Spindle bore | MM | 105 | 105 | 105/130 |

| Spindle speed steps | 4 | 4 | 4 | ||

| Chuck | MM | Manual 400 3-jaws chuck | Manual 400 3-jaws chuck | Manual 630 4-jaws chuck | |

| Lathe bedded | Bed width | MM | 550/600 | 550/600 | 600/700 |

| Feed | x/z fast feed | Mm/ min | 6000/8000 | 6000/8000 | 6000/8000 |

| Tool Turret | Number of tool turret | 4/6/8 | 4/6/8 | 4/6/8 | |

| Tool shank type | MM | 32*32 | 32*32 | 32*32 | |

| Working accuracy | Positioning accuracy | MM | X≤0.02 Z ≤0.025

| X≤0.02 Z ≤0.025 | X≤0.02 Z ≤0.025 |

| Repeatability Positioning accuracy | MM | X≤0.015 Z ≤0.010 | X≤0.015 Z ≤0.010 | X≤0.015 Z ≤0.020 | |

| roundness | MM | ≤0.01 | ≤0.01 | ≤0.015 | |

| Diameter uniformity | MM | ≤0.03(length 300mm) | ≤0.03length 300mm) | ≤0.03length 300mm) | |

| Flatness | MM | ≤0.02(Dia.300mm) | ≤0.02(Dia.300mm) | ≤0.02(Dia.300mm) | |

| Surface roughness | ≤Ra3.2um Steel parts | ≤Ra3.2umSteel parts | ≤Ra3.2umSteel parts | ||

| Tailstock | Dia.of tailstock sleeve | MM | 100 | 120 | 150 |

| Tailstock sleeve taper | MT6 | MT6 | MT6 | ||

| Max. Tailstock sleeve travel | MM | 250 | 250 | 250 | |

| Motor | Spindle drive motor power | KW | 11 | 11 | 11/15 |

| Coolant pump power | KW | 120 | 120 | 120 | |

Related Products