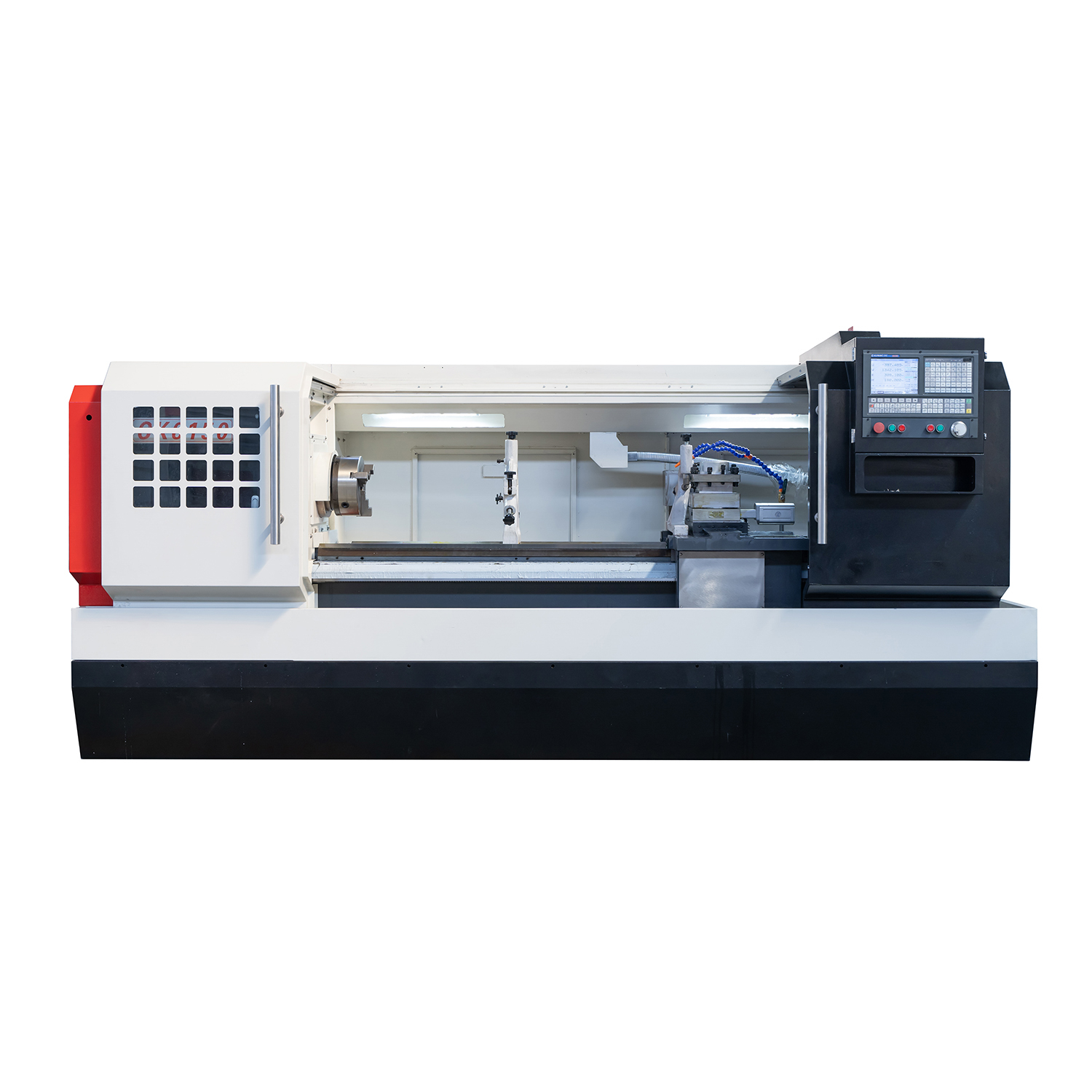

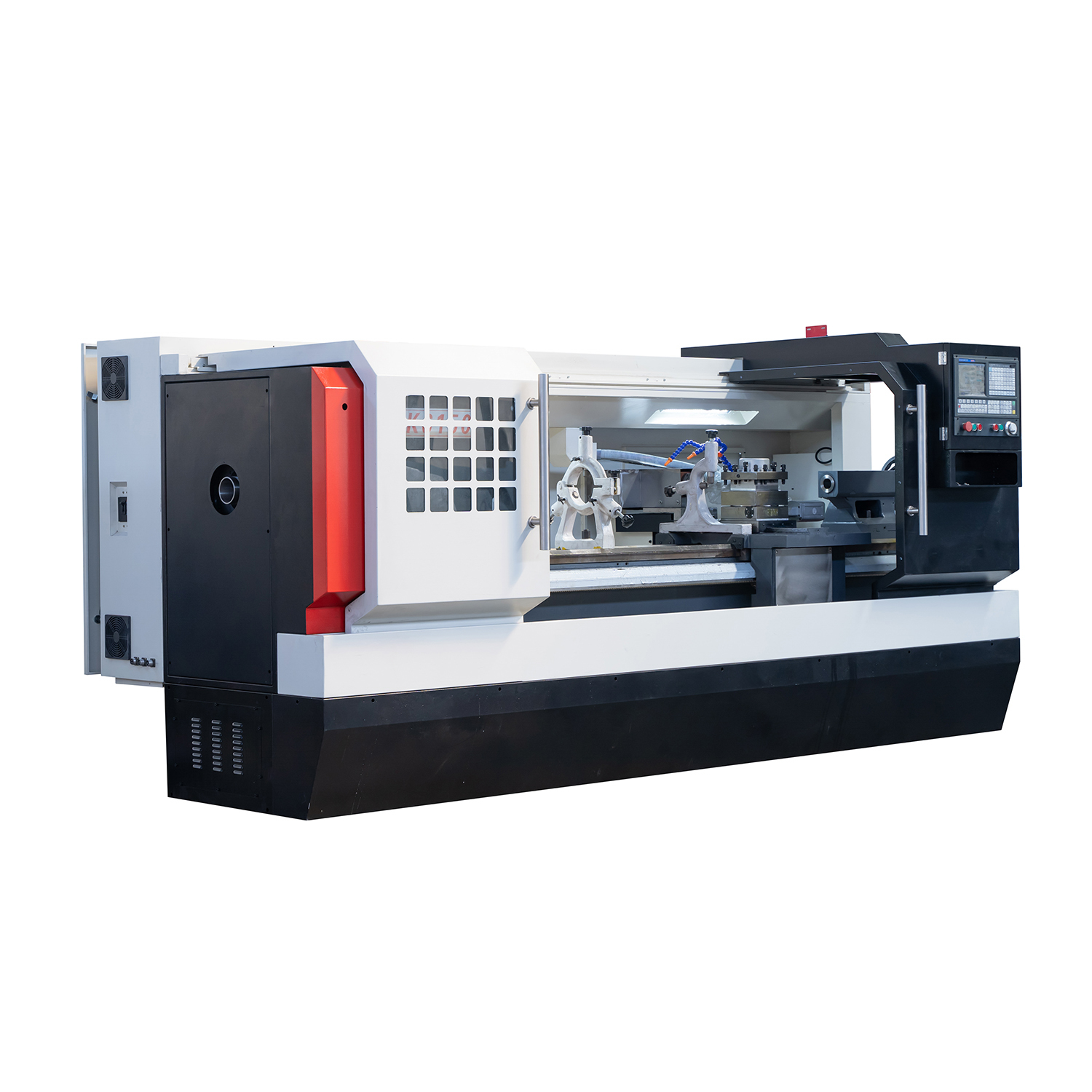

CK6150 Horizontal Cnc Lathe Machine

CK6150 Horizontal Cnc Lathe Machine advantages

- Fully enclosed protection design, good waterproof. Compact layout, saving space,,

- Perfect match of automatic transmission and independent spindle

- Stable precision, high torque, high rigidity, good vibration resistance and high processing efficiency.

- Modular design, independent maintenance-free spindle structure has the characteristics of fast start and stop, stable, efficient and high-precision processing, etc.

- There are two types of spindles: independent spindle and gear box. The independent spindle has the characteristics of high speed and high precision. Gearbox with high torque, heavy cutting, etc.

- High rigidity tailstock design

- VMC Series Vertical Machining Center

- VTC Series Vertical CNC Lathe Machine

- TCK Series Slant Bed CNC Lathe

- WRC Series Wheel Repair CNC Lathe

- QK Series Large Bore Pipe Thread Lathe

- CK Series Horizontal CNC Lathe Machine

- CK Series Heavy Duty CNC Lathe

- CA Series Universal Lathe

- Drilling and Milling Machine

- Sawing Machine

- Slotting Machine and Shape

- Radial Drilling Machine

GET A QUICK REQUESTS

CK6150 Horizontal cnc lathe machine structures are designed, developed, and manufactured by the requirements of international standards. The whole machine has precision and stability, strong rigidity, small thermal deformation of the independent spindle, good precision retention, and excellent maintenance-free characteristics, suitable for heavy cutting. HorizoThe horizontal lathe machine concept has reached the international advanced level. Advanced structural design and perfect supply measures make the machine tool have high reliability and long-term high precision retention.

CK6150 Horizontal cnc lathe Standard configuration

1.GSK980TDi Cnc controller

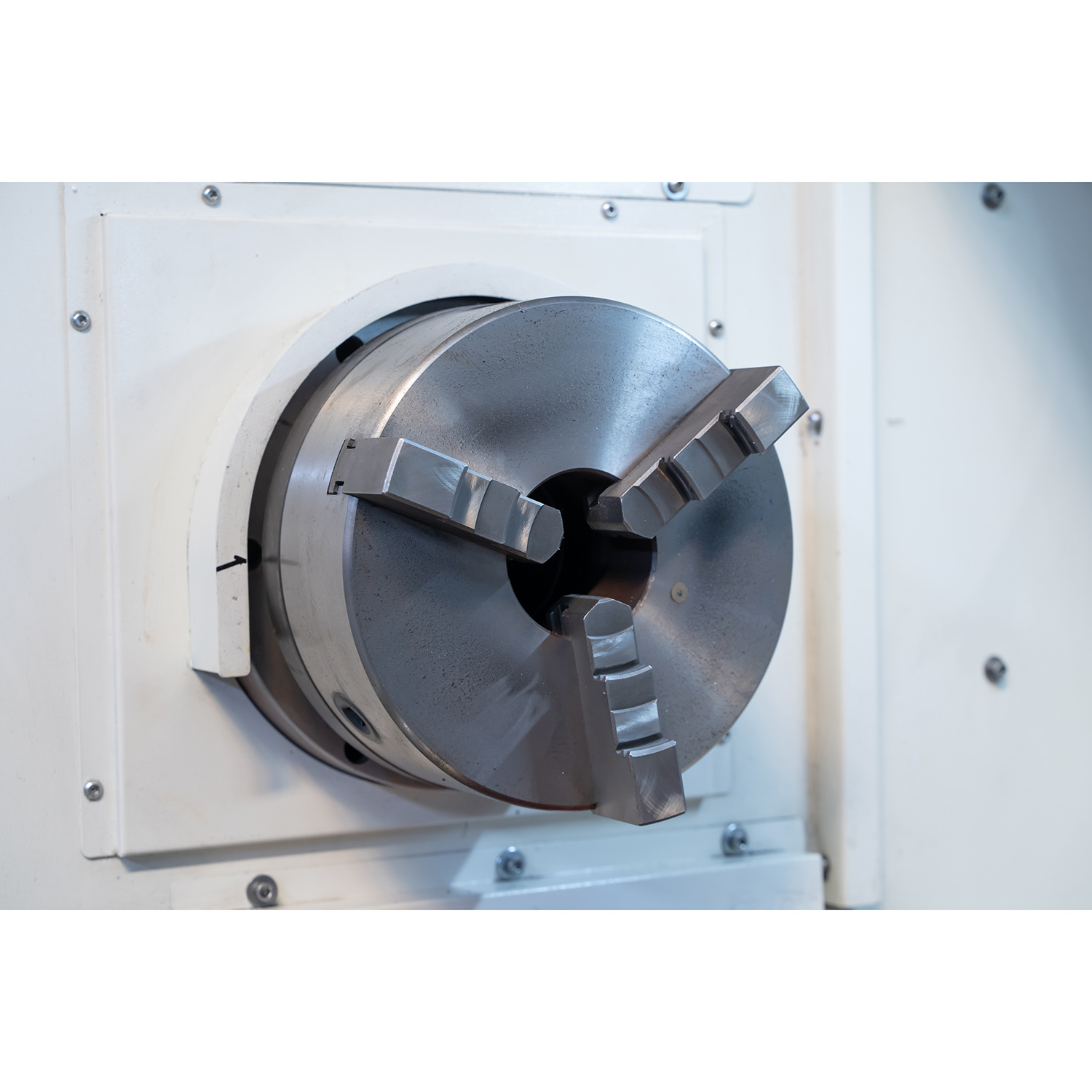

2. Manual 3-jaw 25omm chuck, Manual tailstock

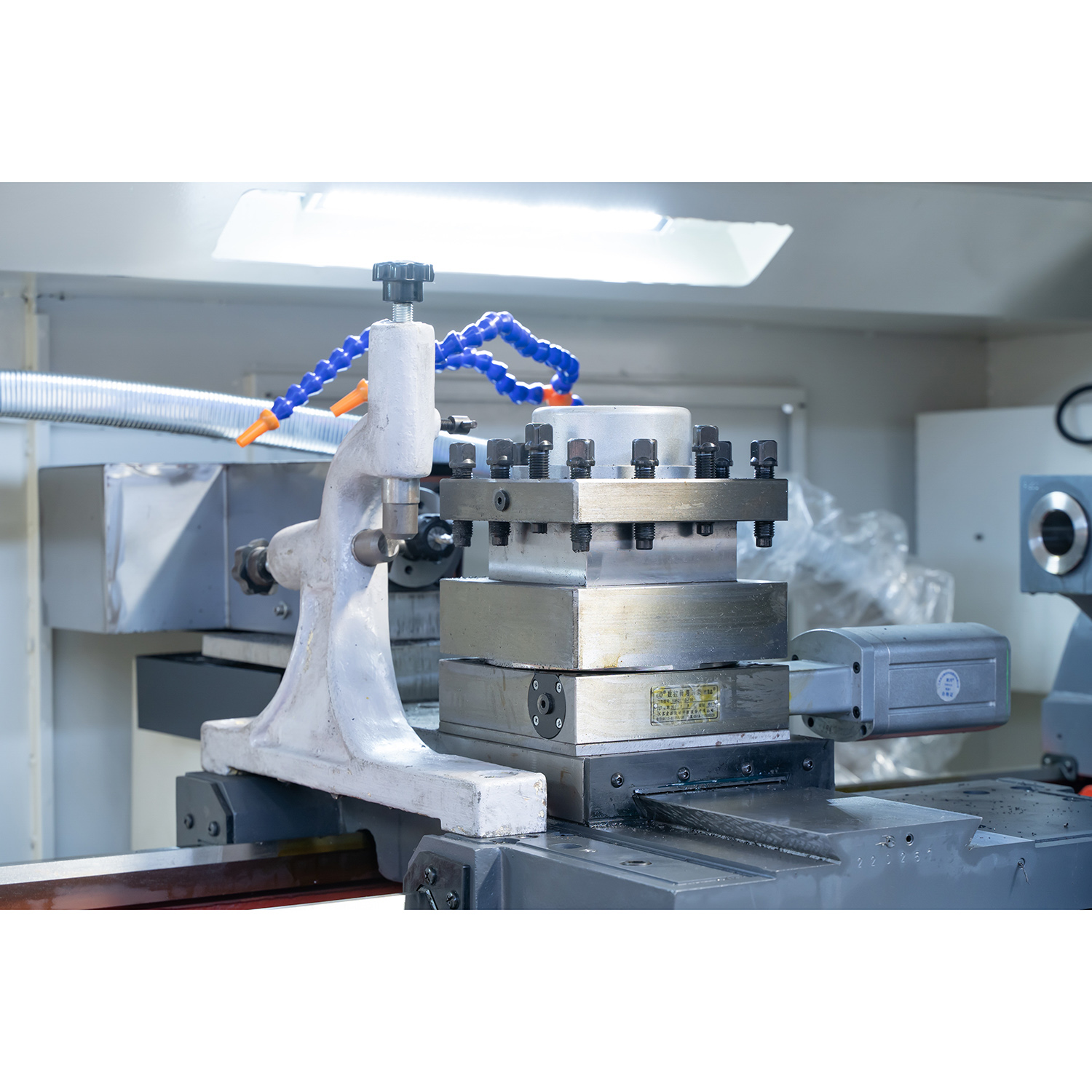

3. Auto Four-station electric turret

4. automatic lubrication

5. Full protection

CK6150 Cnc Lathe Optional configuration

1.KND, SIEMENS,FANUC,SYNTEC

2. Hydraulic Chuck/Hydraulic tailstock, Pneumatic Chuck/Pneumatic tailstock,4-jaw Chuck

3. Automatic change tool 6/8 station turrets

4. Square-cutting power head

5. Equipped with automatic bar feeder (both oil bath type )and servo feeder

CK6150 Horizontal Cnc Lathe Machine Specification

| itm | unit | CK6150FL | CK6150D | CK6161D | CK6166D | CK6180D | |

| Machining Range | Max. Swing over bed | MM | 500 | 500 | 610 | 660 | 800 |

| Max. Swing over cross slide | MM | 300 | 300 | 370 | 400 | 540 | |

| Max. Z axis Travel | MM | 750/1000/1500 | 750/1000/1500/2000/3000 | 750/1000/1500/2000/3000 | 750/1000/1500/2000/3000 | 750/1000/1500/2000/3000 | |

| Max. Z axis Travel | MM | 280 | 260 | 320 | 340 | 410 | |

| Spindle | Spindle bore | MM | 52/82 | 52/80/105 | 52/80/105 | 52/80/105 | 52/80/105 |

| Spindle nose | ISOA2-8 | ISO (GB) D8 | ISO (GB) D8 | ISO (GB) D8 | ISO (GB) D8 | ||

| Spindle speed range | RPM | 150-400/300-1000/600-1600 or 200-2000 | 162-1500 /66-500/21-150 or 50-1800 | ||||

| Spindle speed steps | independent spindle or 3 steps | independent spindles or 3 steps | independent spindle or 3 steps | independent spindle or 3 steps | independent spindle or 3 steps | ||

| Chuck | MM | Manual 3 jaws 250 | Manual 3 jaws 250 | Manual 3 jaws 250 | Manual 3 jaws 250 | Manual 3 jaws 250 | |

| Lathe bed | Bed width | MM | 400 | 400 | 400 | 400 | 400 |

| Feed | x/z fast feed | Mm/ min | 6000/8000 | 5000/10000 | 5000/10000 | 5000/10000 | 5000/10000 |

| x/z cutting travel speed | Mm/ min | 1-6000 | 1-6000 | 1-6000 | 1-6000 | 1-6000 | |

| Tool Turret | Number of the tool turret | 4/6/8 | 4/6/8 | 4/6/8 | 4/6/8 | 4/6/8 | |

| Tool shank type | MM | 25*25 | 25*25 | 25*25 | 25*25 | 25*25 | |

| Working accuracy | Positioning accuracy | MM | X≤0.010 Z ≤0.015 | X≤0.010 Z ≤0.015 | X≤0.010 Z ≤0.015 | X≤0.010 Z ≤0.015 | X≤0.010 Z ≤0.015 |

| Repeatability Positioning accuracy | MM | X≤0.0075 Z ≤0.010 | X≤0.0075 Z ≤0.010 | X≤0.0075 Z ≤0.010 | X≤0.0075 Z ≤0.010 | X≤0.0075 Z ≤0.010 | |

| Min. unit set | MM | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | |

| roundness | MM | ≤0.007 | ≤0.007 | ≤0.007 | ≤0.007 | ≤0.007 | |

| Diameter uniformity | MM | ≤0.03 L:300 | ≤0.03L:300 | ≤0.03 L300 | ≤0.03L:300 | ≤0.03L:300 | |

| Flatness | MM | ≤0.02Dia,300 | ≤0.02 Dia.300 | ≤0.02Dia.300 | ≤0.02Dia.300 | ≤0.02Dia.300 | |

| roughness | Ra1.6um | Ra1.6um | Ra1.6um | Ra1.6um | Ra1.6um | ||

| Tailstock | Dia. of tailstock sleeve | MM | 75 | 75 | 75 | 75 | 75 |

| Tailstock sleeve taper | MT5 | MT5 | MT5 | MT5 | MT5 | ||

| Max. Tailstock sleeve travel | MM | 150 | 150 | 150 | 150 | 150 | |

| Motor | Spindle drive motor power | KW | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Coolant pump power | W | 120 | 120 | 120 | 120 | 120 | |

| size | L W H | MM | 750mm 2550×1550×1900 mm 1000mm 2750×1550×1900 mm 1500mm 3250×1550×1900 mm 2000mm3700×1550×1900 mm 3000mm4710×1550×1900 mm | ||||

| weight | KGS | 750mm NW 2120/ GW 2820 1000mm NW 2240/ GW 3000 1500mm NW2350/ GW 3200 2000mm NW 2740/ GW 3400 3000mm NW 3600/ GW 4200 | |||||

Related Products