- VMC Series Vertical Machining Center

- VTC Series Vertical CNC Lathe Machine

- TCK Series Slant Bed CNC Lathe

- WRC Series Wheel Repair CNC Lathe

- QK Series Large Bore Pipe Thread Lathe

- CK Series Horizontal CNC Lathe Machine

- CK Series Heavy Duty CNC Lathe

- CA Series Universal Lathe

- Drilling and Milling Machine

- Sawing Machine

- Slotting Machine and Shape

- Radial Drilling Machine

GET A QUICK REQUESTS

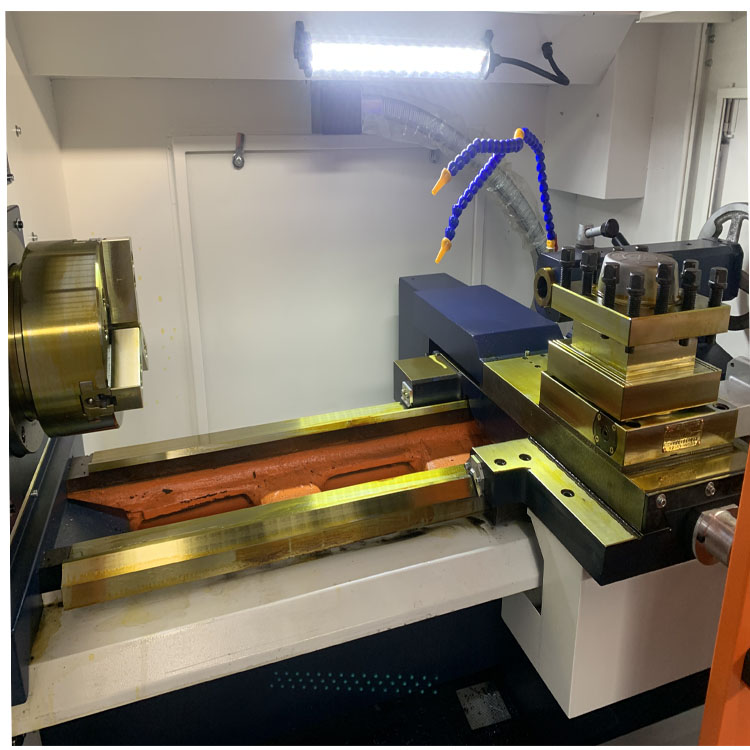

CK6140F series Metal cnc lathe factory has the characteristics of high precision, high power, high rigidity, etc., and its main components and structures have been optimized.

GSK980TDC or FANUC 0i-mate CNC system and full-digital AC servo system, X and Z axes adopt semi-closed-loop control, ball screw pair adopts C3 level precision ball screw, electrical components are imported or domestic famous brands, conform to CE Or domestic 3C certification.

The machine tool is equipped with a domestic well-known brand vertical four-station CNC tool post, and can be equipped with a six-station or eight-station horizontal electric tool post. The tool post has the characteristics of high positioning accuracy, high strength, and good shock resistance.

Before leaving the factory, the machine tool is inspected in strict accordance with the inspection procedures. Each machine tool uses a laser interferometer to detect the positioning accuracy and repeatability of the X and Z axes to ensure the stability and reliability of the machine tool.

CK6140F Cnc Lathe Machine

1.Cnc Controller: GSK/KND/Fanuc/Siemens/Syntec/Mitsubishi

2.Chuck: Manual Chuck 2oomm/250mm, Hydraulic Chuck

3.Chuck jaw:2/3/4 jaws

4.Spindle Bore:52mm/60mm/80mm

5.Tailstock: Manual/ Hydraulic

6.Fully automatic lubrication system

7.Leveling screw and footings

8.Cutting blow device

9.Operating instruction

10.Basic toolbox

CK6140F Cnc Lathe Machine Specification

| ITM | unit | CK6136FL/CK6140FL | CK6146 | |

| Machining Range | Max. Swing over bed | MM | 360/400 | 460 |

| Max. Swing over cross slide | MM | 220 | 230 | |

| Max. work length | Mm | 600/850/1350 | 750 | |

| Max. Z axis Travel | MM | 750/1000/1500 | 1000 | |

| Max. X axis Travel | MM | 250 | 250 | |

| Spindle | Spindle bore | MM | 52 | 66 |

| Spindle nose | A2-6 | A2-6 | ||

| Spindle speed range | RPM | 100-2500 | 100-2500 | |

| 100-750,500-1500 | 90-500/400-800/600-1700 | |||

| Spindle type | Independent spindle Manual 2 steps | Manual 3steps Independent spindle | ||

| Chuck | MM | 200mm manual 3 jaws | ||

| Lathe bed | Bed width | MM | 360 | 380 |

| Feed | x/z fast feed | Mm/min | 6000/8000 | |

| x/z cutting travel speed | Mm/min | 1-6000 | ||

| Tool Turret | Number of tool turret | 4/6/8turret | 4/6/8turret | |

| Tool shank type | MM | 20*20 | 25*25 | |

| Working accuracy | Positioning accuracy | MM | X≤0.010 Z ≤0.015 | |

| Repeatability Positioning accuracy | MM | X≤0.0075 Z ≤0.010 | ||

| Min. unit set | MM | 0.001 | ||

| roundness | MM | ≤0.007 | ||

| Diameter uniformity | MM | ≤0.03 (length 300) | ||

| Flatness | MM | ≤0.02 (Diameter 300) | ||

| Surface Roughness (Steel) | Ra1.6um | |||

| Tailstock | Dia. of tailstock sleeve | MM | 60 | 60 |

| Tailstock sleeve taper | MT4 | MT5 | ||

| Max. Tailstock sleeve travel | MM | 140 | 140 | |

| Motor | Spindle drive motor power | KW | 5.5 | 5.5 |

| Coolant pump power | W | 120 | 120 | |

| size | L W H | MM | 2200X1500X1750 | 2150X1400X1660 |

| weight | 1.6T | 1.7T | ||

Related Products