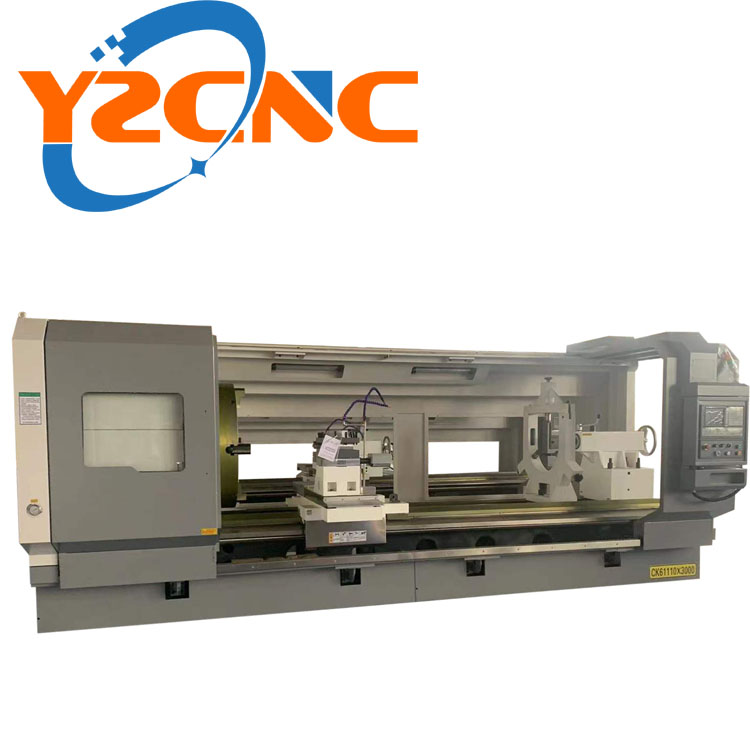

CK61125 heavy-duty lathe

Heavy-Duty Lathe Standard Configuration :

GSK980TC3/Siemens/Fanuc

3 jaws manual chuck

4/6/8/12 station electric turret

manual tailstock

Certification: CE/SGS

Type: Horizontal Lathe or Vertical Lathe

Warranty: 18 months

Voltage: As customers’ requirement (380V/400V/220V)

Color: As customers’ requirement

After-sale service: Overseas door-to-door installation and commissioning can be provided

Brand Name:YZCNC

- VMC Series Vertical Machining Center

- VTC Series Vertical CNC Lathe Machine

- TCK Series Slant Bed CNC Lathe

- WRC Series Wheel Repair CNC Lathe

- QK Series Large Bore Pipe Thread Lathe

- CK Series Horizontal CNC Lathe Machine

- CK Series Heavy Duty CNC Lathe

- CA Series Universal Lathe

- Drilling and Milling Machine

- Sawing Machine

- Slotting Machine and Shape

- Radial Drilling Machine

GET A QUICK REQUESTS

A heavy-duty lathe, also known as an engine lathe or a large Horizontal lathe, is a type of lathe designed to handle large and heavy workpieces. This machine tool is primarily used for machining large-diameter and long-length cylindrical components, such as shafts, rolls, tubes, and cylinders, in various industries. The main feature of a heavy-duty lathe is its robust and sturdy construction, which allows it to handle heavy and demanding machining operations with high accuracy and precision.

A heavy-duty lathe, also known as an engine lathe or a large Horizontal lathe, is a type of lathe designed to handle large and heavy workpieces. This machine tool is primarily used for machining large-diameter and long-length cylindrical components, such as shafts, rolls, tubes, and cylinders, in various industries. The main feature of a heavy-duty lathe is its robust and sturdy construction, which allows it to handle heavy and demanding machining operations with high accuracy and precision.

The main features of a heavy-duty lathe include the following:

Heavy-Duty Lathe Bed: The bed is the main structural component of a cnc lathe, which provides a solid and stable platform for mounting the headstock, tailstock, and carriage. In a heavy-duty lathe, the bed is usually made of cast iron or steel, and it is designed to handle the weight and vibrations generated during machining operations.

Lathe Headstock: The headstock is located at the left end of the bed, and it contains the main spindle, which rotates the workpiece. The spindle is usually driven by an electric motor, and it can be adjusted for speed and direction. In a heavy-duty cnc lathe, the headstock is designed to handle large and heavy workpieces, and it may have a hydraulic or pneumatic chuck for gripping the workpiece.

Lathe Tailstock: The tailstock is located at the right end of the bed, and it supports the opposite end of the workpiece. It can be moved along the bed to adjust the length of the workpiece, and it may have a center or a chuck for holding the workpiece. In a heavy-duty lathe, the tailstock is usually equipped with a hydraulic or pneumatic system for clamping and releasing the workpiece.

Lathe Carriage: The carriage is part of the lathe machine that holds the cutting tool and moves along the bed to perform the cutting operation. It consists of a saddle, a cross-slide, and a tool post. In a heavy-duty lathe, the carriage is designed to handle the weight and forces generated during machining operations, and it may have a power-driven feed system for automating the cutting process.

Lathe Tooling: The cutting tool is the most important component of the lathe, which removes material from the workpiece to create the desired shape and size. In Horizontal heavy duty Cnc lathe, the cutting tool is usually made of high-speed steel or carbide, and it may have a large diameter and a special geometry to handle the heavy cutting forces.

Heavy-duty Lathe Have Cnc and no Cnc ,Main model has CK6163 CK6180 CK61100 CK61125 CK61600

CK61125 heavy-duty lathe Specification

| itm | unit | CK61125 | |

| Machining Range | Max. Swing over bed | MM | 1250 |

| Max. Swing over cross slide | MM | 880 | |

| Max. center distance | MM | 1500/2000/3000 | |

| Spindle | Spindle bore | MM | 105/130 |

| Spindle speed steps | 4 | ||

| Chuck | MM | Manual 630 4-jaws chuck | |

| Lathe bed | Bed width | MM | 700/755 |

| Feed | x/z fast feed | Mm/ min | 6000/8000 |

| Tool Turret | Number of tool turret | 4/6/8 | |

| Tool shank type | MM | 32*32 | |

| Working accuracy | Positioning accuracy | MM | X≤0.02 Z ≤0.025 |

| Repeatability Positioning accuracy | MM | X≤0.015 Z ≤0.020 | |

| roundness | MM | ≤0.015 | |

| Diameter uniformity | MM | ≤0.03(length 300mm) | |

| Flatness | MM | ≤0.02(Dia.300mm) | |

| Surface roughness | ≤Ra3.2umSteel parts | ||

| Tailstock | Dia.of tailstock sleeve | MM | 150 |

| Tailstock sleeve taper | MT6 | ||

| Max. Tailstock sleeve travel | MM | 250 | |

| Motor | Spindle drive motor power | KW | 18/22 |

| Coolant pump power | KW | 120 | |

The heavy-duty lathe is a versatile machine tool that can be used in various industries, such as:

Aerospace: The aerospace industry requires large and complex components, such as aircraft engines, landing gears, and wings, which can be machined using heavy-duty lathes. These machines can handle high-precision machining operations, such as turning, drilling, boring, and threading, and they can produce parts with tight tolerances and smooth surface finishes.

Energy: The energy industry requires large and heavy components, such as turbines, generators, and pumps, which can be machined using heavy-duty lathes. These machines can handle heavy cutting forces and produce parts with high accuracy and repeatability.

Oil and Gas: The oil and gas industry requires large and sturdy components, such as drilling pipes, casings, and valves, which can be machined using heavy-duty lathes. These machines can handle rough and tough materials, such as steel, iron, and titanium, and produce parts with high strength and durability.

Heavy Equipment: The heavy equipment industry requires large and robust components, such as excavator arms, bulldozer blades, and crane booms, which can be machined using heavy-duty

Related Products