- VMC Series Vertical Machining Center

- VTC Series Vertical CNC Lathe Machine

- TCK Series Slant Bed CNC Lathe

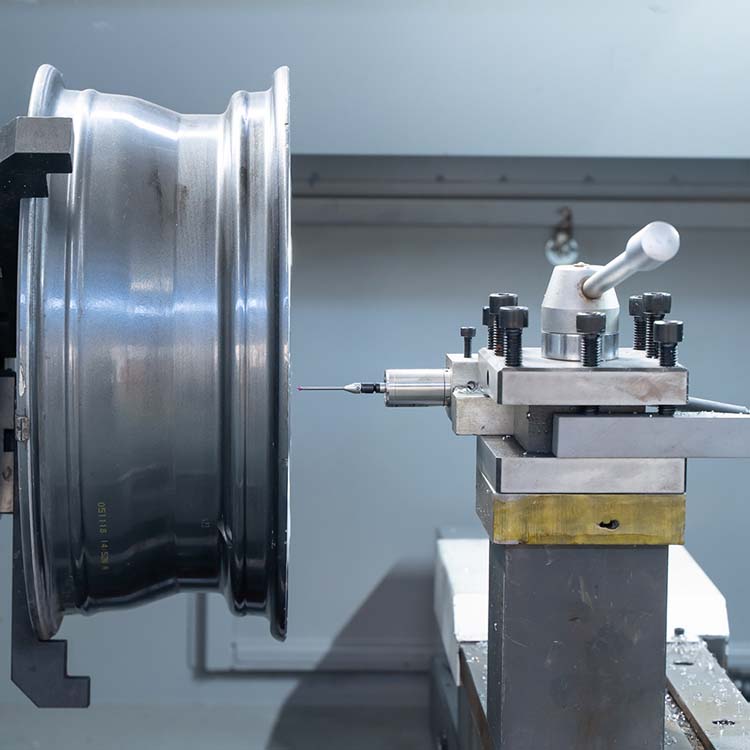

- WRC Series Wheel Repair CNC Lathe

- QK Series Large Bore Pipe Thread Lathe

- CK Series Horizontal CNC Lathe Machine

- CK Series Heavy Duty CNC Lathe

- CA Series Universal Lathe

- Drilling and Milling Machine

- Sawing Machine

- Slotting Machine and Shape

- Radial Drilling Machine

GET A QUICK REQUESTS

YZCNC Company specializes in the production of wheel hub refurbishment equipment, products have Alloy Wheel Lathe CNC Machines, Wheel Straightening Tools, Alloy Rim Polishing Machines, CNC Diamond Cutting Lathe, Alloy Rim Repair Equipment, Advanced CNC Machine Software.WRC20 Alloy Rim Repair Lathe Small footprint, simple and convenient operation.

Wheel repair lathe is a professional equipment developed by our company according to market development, user needs, and feedback, which is specially designed for wheel refurbishment, modification, and color change. The company has more than 25 years of experience in the production of CNC machine tools. Product quality is trustworthy. At present, there are two main types of machine equipment: vertical and horizontal. The model can be selected according to the size of the processing wheel. The largest wheel can reach 32 inches.

Alloy Rim Repair Lathe Equipment Main Feature

- The operation of the machine is simple and convenient, there is no professional requirement for the operator, and the zero-based can also be quickly mastered.

- The system is free of programming and has fast work efficiency. It can automatically detect the shape of the hub, collect data, generate processing programs, and automatically cycle cutting.

- Advanced intelligence can meet the diverse shapes of hubs on the market, the system is continuously upgraded, and there is no dead angle for detection and processing, such as high edge steps, double steps, and special-shaped hubs can be processed.

- The detailed processing is perfect, the texture is uniform and clear, and the finish is high.

- The system can be customized, such as adding the user’s boot logo, and the button can change the language that the user is more accustomed to, etc.

- The system has a remote service function, which can upgrade and update the user’s machine, teaching and training, after-sales service, and other functions

- High-cost performance, less tool wear, and low material cost.

- We are a real manufacturer. We pay more attention to product quality, details and services, and the user’s sense of applicable experience, and develop more user-friendly and high-quality products according to market development.

Alloy Rim Repair Lathe Equipment Specification

| ITM | UNIT | WRC20H | |

| Machine processing capacity Maxx | Max. swing over bed | Mm | 700 |

| X/Z axis Travel | mm | 315/500 | |

| X/Z axis feed | Mm/min | 4000/8000 | |

| Wheel work range holding holding | holding diameter | inc | 20 |

| Wheel height range | mm | 80-350 | |

| Chuck | Chuck size | mm | 250 |

| Number of chuck jaws | 3/4/6 | ||

| Spindle speed lathe | Lathe speed | Rpm/min | 100-1500 |

| Cut Wheel Work Speed | 300-800 | ||

| Detection tools | TP300探针 Probe | ||

| Guide rail form | Hard rail | ||

| Lathe structure | Horizontal system | ||

| system | 6Ta-E / YZCNC(Automatic programming,touch screen operation 17inch screen LCD display) | ||

| tool carrier number | Number | 4 | |

| accuracy | Positioning accuracy | Mm | 0.01 |

| Repeatability Positioning accuracy | mm | 0.005 | |

| Tool carrier Repeatability Positioning accuracy | mm | ±0.07 | |

| Motor power main | Main motor | kw | 4 |

| X Z Feed Torgue | N/M | 6/10 | |

| Cooling | Water cooling/air cooling/high-pressure spray cooling | ||

| Voltage | Single 220v 3 phase 220v 3 phase 380V | ||

| Machine size | mm | 1950/1360/1600 | |

| Machine weight | T | 1.0t | |

Related Products