At present, our company’s CNC lathes, vertical machining centers, and CNC vertical lathes can be equipped with mechanical arms. The machine replaces the human, and it replaces the weakness of the human n being. For example, the machine can work 24 hours a day, and the machine can better avoid work-related injuries. The unmanned factory does not eliminate workers but liberates workers from certain labors to play more There are creative roles. Technological changes will take away some low-end and tedious jobs, but will also create higher-end jobs. As long as you improve your quality, you will never have to worry about being replaced by machines.

n being. For example, the machine can work 24 hours a day, and the machine can better avoid work-related injuries. The unmanned factory does not eliminate workers but liberates workers from certain labors to play more There are creative roles. Technological changes will take away some low-end and tedious jobs, but will also create higher-end jobs. As long as you improve your quality, you will never have to worry about being replaced by machines.

Intelligent production line integrating intelligent robots and CNC equipment

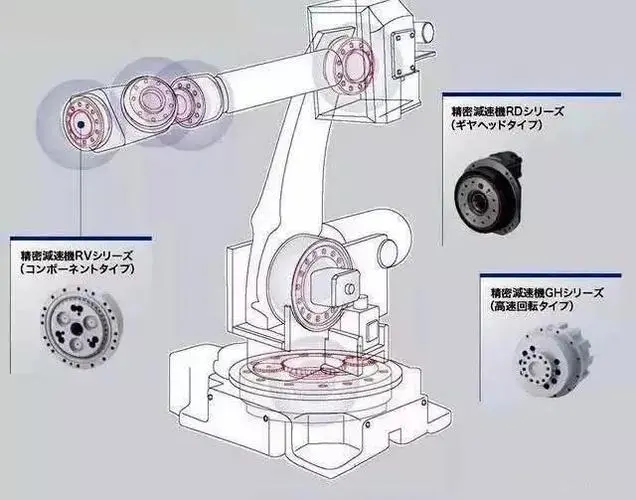

The high-end demand for CNC equipment automation continues to be dominated by high value-added and complex production lines, and business needs extend upstream and downstream and extend to applications such as tooling and fixtures, automatic logistics, three-dimensional warehousing, system control, and MES. Based on this, combined with engineering practice, this paper focuses on the analysis of the “intelligent manufacturing” flexible production line design and automation control ideas of industrial robots so that robots and CNC machining can be integrated to realize the automation and unmanned processing of parts. CNC equipment integration; industrial robot; intelligent manufacturing system

Current status of integrated application of industrial robots and CNC equipment

At present, the status quo of the integrated application of industrial robots and machine tools is mainly based on machine tools completing the processing process, while robots only complete the loading and unloading and logistics between processes. In terms of ancestors, it is also divided into:

1. Single-machine loading and unloading As for the processing of small and medium-sized parts with large production batches and short processing time, or heavy workpieces that need to be hoisted, the advantages of robot loading and unloading are particularly obvious.

1. Single-machine loading and unloading As for the processing of small and medium-sized parts with large production batches and short processing time, or heavy workpieces that need to be hoisted, the advantages of robot loading and unloading are particularly obvious.

2. In addition to single-machine loading and unloading, there are also flexible production lines composed of multiple machine tools and various processes. The layout of the machine tool depends on factors such as the process route and site conditions. The robot undertakes the process conversion of the workpiece and forms a flexible production line together with the machine tool.

3. On some metal-forming machines, robots complete the process along with the machine tool. The robot clamps the workpiece to realize the processing operation on the punching, shearing, and bending machine, which is not only a simple loading and unloading but also replaces all the original manual work.

4. In individual processes, process robots participate in specific processing, cutting, polishing, grinding, etc. for robots, and even robots directly hold cutting tools to realize the drilling of workpieces. A robot with vision and touch is equivalent to a machine tool, which can be used for complex tasks such as assembly and parts sorting.

what is an Industrial robot?

It can be seen from the application analysis of the current situation of the integration of intelligent robots and CNC equipment that their specific integrated application forms are also being continuously explored and innovated, and industrial robots are used as a standard component. How to apply integration is the key direction of our next step in the research of CNC machine tools that integrate robots. And our company formally starts from this point to provide a complete set of technical solutions, from machine tool equipment to manufacturing units integrated with industrial robot automation, to provide customers with overall automation projects. This requires breaking through the barriers of robots and CNC equipment control systems, unifying automation ideas, unifying digital interfaces, unifying operation interfaces, and seamless connections. At the same time, through automated logistics and storage systems, automated workstations of different professions will also be opened up to modules. Breakthroughs in the directions of automation, integrated unmanned manufacturing unit, information automation, and logistics automation

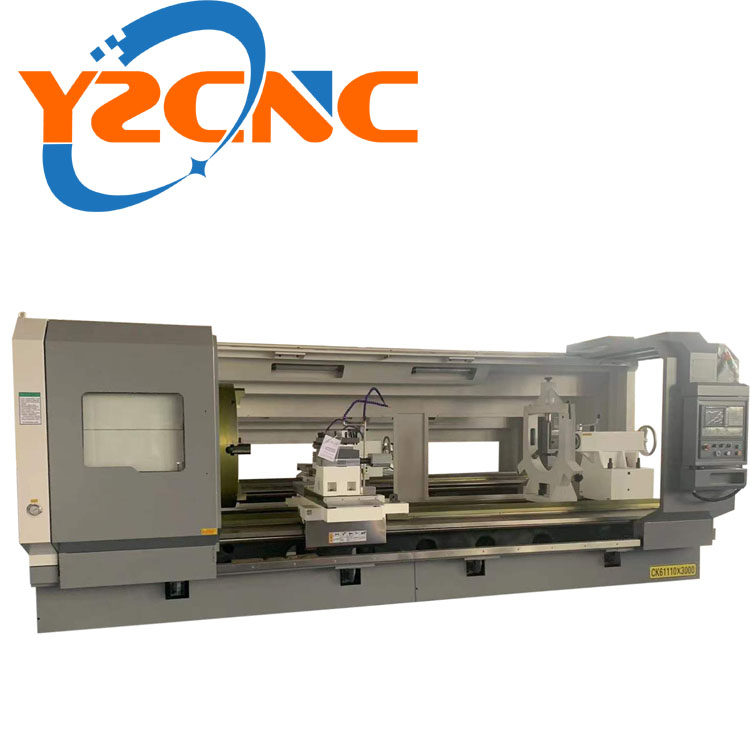

Industrial Robots and CNC Machine Tools

In response to the demand for automation of motor shell manufacturing proposed by a certain company, an intelligent production line was developed according to the workpiece process flow, which is composed of industrial robots, machining centers, CNC lathes, and system control cabinets. Integrating machine vision detection technology, PLC control technology, sensor technology, industrial Internet, manufacturing execution system, and other technologies to realize integrated control of loading, processing, unloading, testing, etc. Through PLC control detection and process and system scheduling, manufacturing execution system MES management and control information visualization and real-time data analysis and processing, effectively integrate digital twin technology, information communication technology, and automation technology, and run through the whole industrial chain of design-process manufacturing debugging.

In response to the demand for automation of motor shell manufacturing proposed by a certain company, an intelligent production line was developed according to the workpiece process flow, which is composed of industrial robots, machining centers, CNC lathes, and system control cabinets. Integrating machine vision detection technology, PLC control technology, sensor technology, industrial Internet, manufacturing execution system, and other technologies to realize integrated control of loading, processing, unloading, testing, etc. Through PLC control detection and process and system scheduling, manufacturing execution system MES management and control information visualization and real-time data analysis and processing, effectively integrate digital twin technology, information communication technology, and automation technology, and run through the whole industrial chain of design-process manufacturing debugging.

Motor shell processing automatic production line

The motor casing is processed in large quantities, and the material is aluminum alloy. The processing content includes face milling and drilling, tapping and inner hole turning, etc., fully considering the necessary turning, loading, unloading, guiding and positioning, and signal when the workpiece is transferred between various processes. Testing and other requirements, combined with the processing content, comprehensively analyzed the process beat, and finally determined the content of the part processing process as follows:

1 Vertical Machining Center Drilling threaded bottom holes, tapping threads, and milling outer bosses.

1 Vertical Machining Center Drilling threaded bottom holes, tapping threads, and milling outer bosses.

2 Machining center for through hole, hole chamfering process

3 Numerical control lathe for inner hole and step hole, hole chamfering process processing.

4 According to the shape and characteristics of the workpiece, design the pneumatic gripper parts of the robot, including pneumatic, sensor, and mechanical parts, etc. The machining center fixture adopts the internal clamping method, and the CNC lathe adopts the external clamping method. The blank workpiece is placed on the feeding conveyor belt. The robot R1 composite claw grabs the blank workpiece, walks to the machining center, and installs the workpiece on the special fixture of the machining center. After the processing of the machining center is completed, the robot R1 composite claw takes Lower the workpiece, walks on the position of the machining center, and installs the workpiece on the special fixture of the machining center, after the machining center is finished, the robot R1 removes the workpiece to the position of the CNC lathe, installs the workpiece on the special fixture, and removes the workpiece after the machining of the upper part is completed. After placing the workpiece, the robot walks to the position of the turning table for turning and exchanging the workpiece. After the workpiece is exchanged on the turning table, robot R1 places the finished product on the unloading conveyor belt, and robot R2 unloads the workpiece and automatically stacks it in the finished product basket. . After adjusting the CNC processing program and robot action program, the perfect combination of CNC machine tool processing and robot loading and unloading can be realized.

Automatic machine tool production lines and highly automated processing equipment have become a development trend in manufacturing plants in  the future. Automatic loading and unloading devices such as single-machine automation and whole-line automation are used for the automatic loading and unloading of workpieces, workpiece flipping, workpiece reordering, etc. It can meet the requirements of fast and large-scale processing, save labor costs, and improve production efficiency. The automatic processing production line of the motor shell integrates advanced technologies such as robot technology, PLC technology, sensor detection technology, communication technology, and numerical control technology. Realize the technical combination of industrial robots and CNC machine tools, establish a program transmission management system, production data collection and analysis management, workshop real-time visual feedback system, and realize the collection and analysis of the production data of the entire production line, thereby improving the overall production and operation efficiency of production equipment, reducing Reduce production costs, improve product quality, and bring greater profit margins to customers

the future. Automatic loading and unloading devices such as single-machine automation and whole-line automation are used for the automatic loading and unloading of workpieces, workpiece flipping, workpiece reordering, etc. It can meet the requirements of fast and large-scale processing, save labor costs, and improve production efficiency. The automatic processing production line of the motor shell integrates advanced technologies such as robot technology, PLC technology, sensor detection technology, communication technology, and numerical control technology. Realize the technical combination of industrial robots and CNC machine tools, establish a program transmission management system, production data collection and analysis management, workshop real-time visual feedback system, and realize the collection and analysis of the production data of the entire production line, thereby improving the overall production and operation efficiency of production equipment, reducing Reduce production costs, improve product quality, and bring greater profit margins to customers