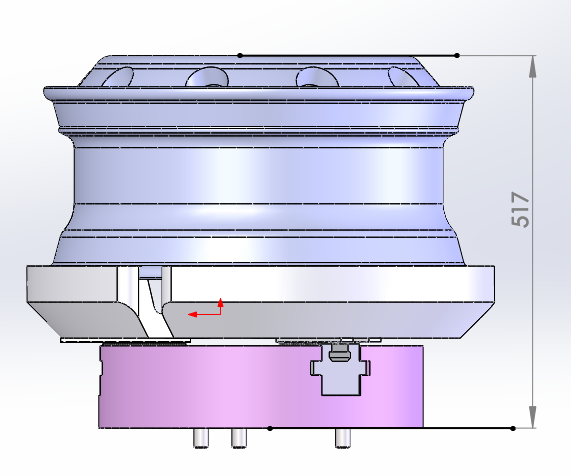

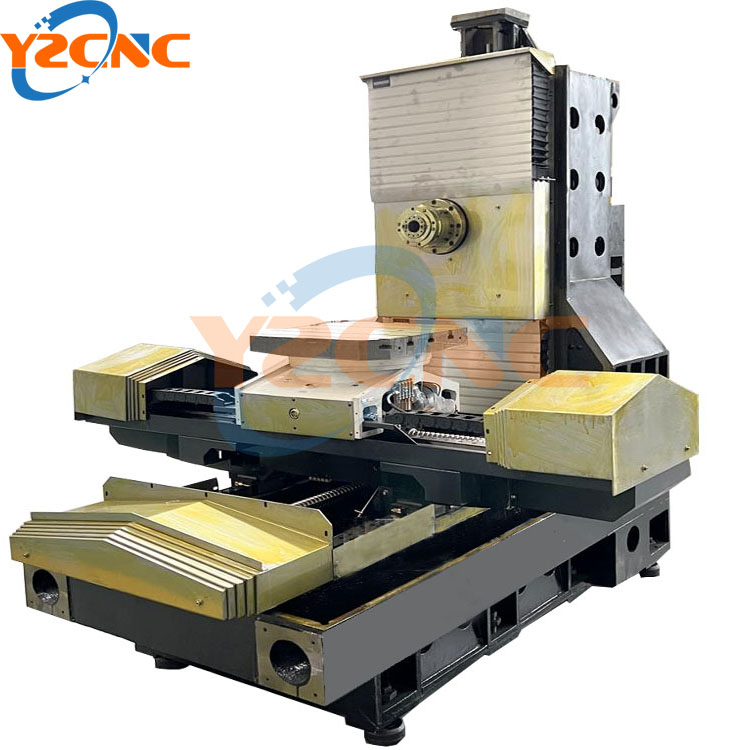

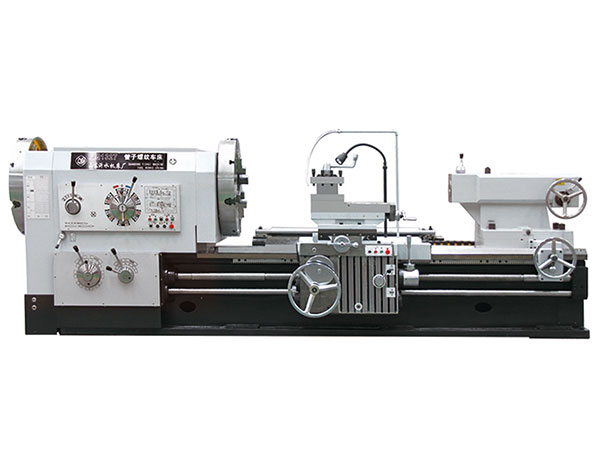

The Difference between CNC machine tools has cnc lathe machine, Cnc milling machine, Vertical cnc machining center, slant bed machine tools and vertical cnc lathe machine. All machine tools need to do daily maintenance.

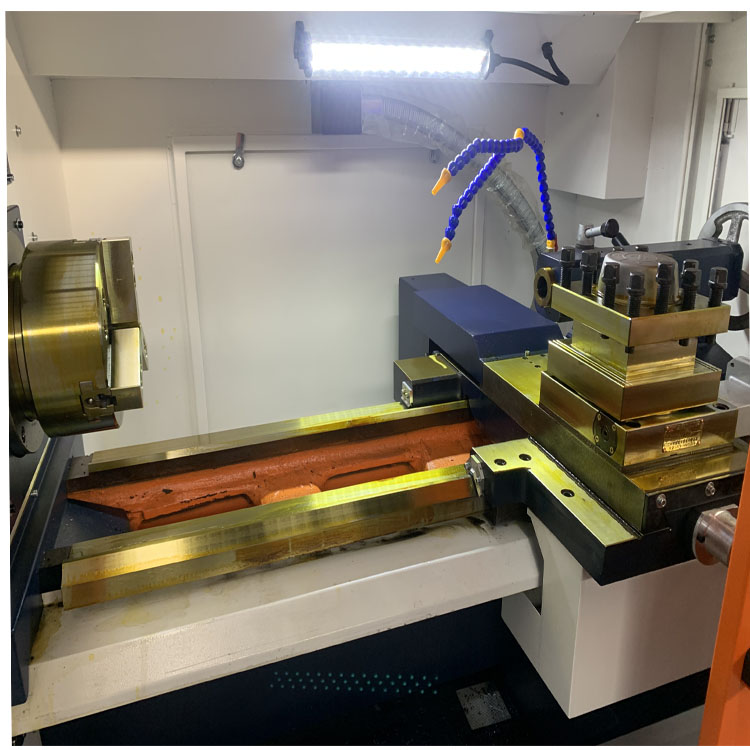

How to maintain the Cnc lathe machine tool irregularly?

( 1) Check the liquid level of the cooling oil tank and water tank from time to time, add oil or water in time, and clean and replace it in time when it is dirty.

( 2) Check the waste oil pool from time to time, and remove the collected waste oil in time to prevent overflow.

( 3) The chip conveyor should clean up the chips frequently and check for jamming.

( 4) Check the main spindle drive belt from time to time, adjust the tightness of the belt as required, and replace it in time if it is damaged.

( 5) From time to time, check the guide rail inserts of each axis, press the rollers, and adjust the tightness according to the instructions.

( 6) Clean the old grease on the crew every six months and apply new grease.

( 7) Clean the overflow valve, valve, oil filter, and oil tank every six months, and filter or replace the hydraulic oil.

( 8) Clean the spindle lubricating oil tank every year and replace the lubricating oil.

( 9) Check and replace motor brushes every year, blow off carbon powder, and remove burrs.

( 10) Clean the bottom of the lubricating oil pool and replace the oil filter every year

What is the daily maintenance and maintenance work of cnc machining center machine tool?

( 1) Check the lubricating oil tank of the guide rail every day, the oil mark and the amount of oil, and add lubricating oil in time.

( 2) Check the surface of the guide rail for scratches and damage, and remove chips and dirt.

( 3) Check the compressed air source, the pressure of the pneumatic control system should be within the normal range.

( 4) Check the air source automatic water separation filter every day to keep the air dryer working normally.

( 5) When the oil level of the pneumatic converter and supercharger is not enough, it is necessary to increase the oil in time.

( 6) To ensure the normal operation of the spindle constant temperature lubricating oil tank.

( 7) Check whether the pressure index of the hydraulic balance system is normal, and whether the balance valve works normally when moving quickly.

( 8) Check whether there is abnormal noise in the oil tank and oil pump of the hydraulic system of the machine tool, whether the index of the pressure gauge is normal, whether there is leakage in the pipeline and each joint, and whether the height of the working oil level is normal.

( 9) Ensure that the ventilation and heat dissipation devices and cooling fans of the electrical cabinet are normal.

( 10) Clean the filter screen of the electrical cabinet every week.