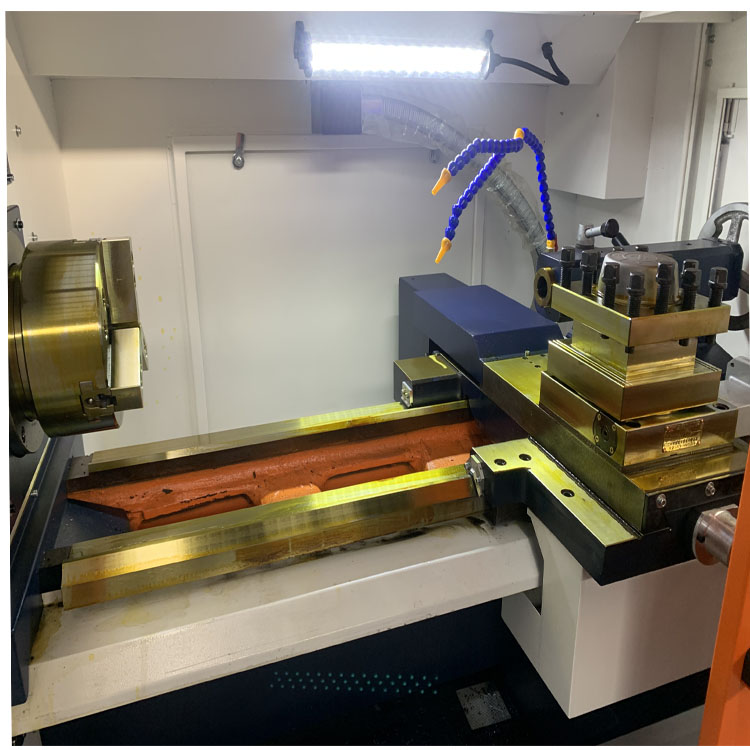

Metal spinning forming uses the feeding motion of tools such as a rotating wheel to press a metal blank(metal sheet or pipe) that is rotated with the spindle of a random bed to produce continuous local plastic deformation and become the required hollow. A non-cutting machining process for rotating parts.

A preform is clamped against a spinning chuck and set in rotation. The spinning roller forms the preforming step by step until the material has been brought onto the spinning chuck. Rotating tools generate a variety of surface lines on the workpiece, which is also rotating so that the final form of the workpiece is generated and the surface is smoothed.

A variety of other, additional machining processes can be performed in the same clamping setup, such as the subsequent profiling of contour areas, the separation of marginal or base areas, the bordering of external edges, etc. In this way, virtually and type of hollow body can be produced with complicated or complex geometries, very narrow tolerances, and excellent surfaces.

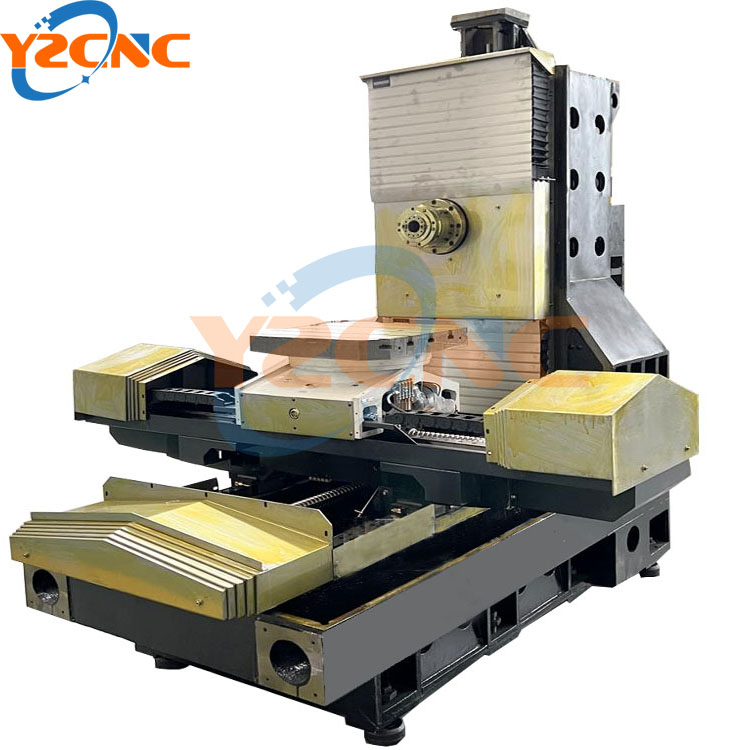

Spinning lathe Material

Aluminum/Aluminum alloy/carbon steel/stainless steel/Stainless steel/titanium alloy/platinum/copper/gold/silver/molybdenum/various high-temperature alloys

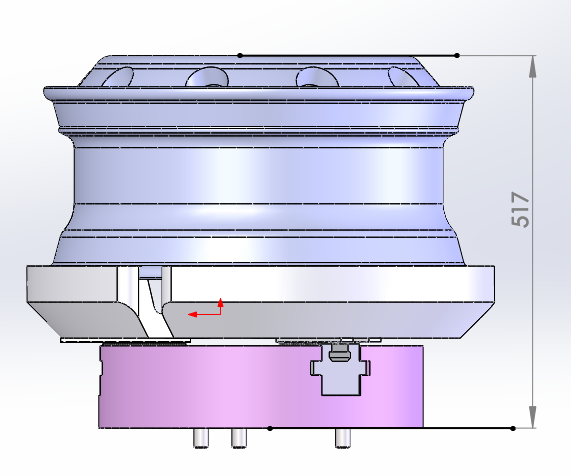

Spinning lathe spinning process principles

The spinning chipless forming process is to make the metal circle blank, tube billet, and pre-formed material enter a rotary motion. The rotating metal blank is squeezed by the forming foller and the metal begins to flow. This process can obtain a variety of hollow bodies with complex generatrix shapes, small tolerance ranges, excellent material properties, and surface quality with minimal tooling cost. The spinning process accurately determines the wall thickness and profile of the workpiece and accurately repeats the wall thickness and contour.

Spinning lathe the theory of spinning technology

- Chipless metal forming

- High efficiency

- High manufacturing potential

- Low tooling costs

- Low initial investment

- Fast process

- Wide product range

- Solve the problem of manual spinning

- Easy operation

- Flexibility

- High production rate for mass production

- Product consistency

- Customerized technical support

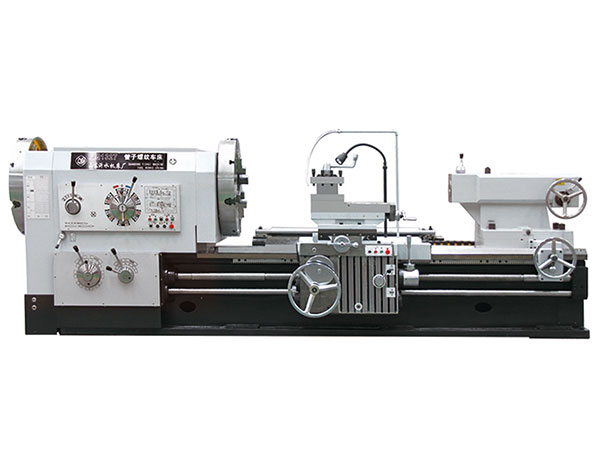

Spinning lathe Application field

| lighting | construction |

| kitchenware | Hardware |

| Aerospace | engineering |

| aviation | Musical instrument |

| automobile | Medical |

| military | Agriculture |

| chemical | Gas |

| Fan | communication |

| Air conditioning | Motorcycle |

| power | shipbuilding |

| ventilation | Rail transit house |

| House wares | environmental |

| Packing | oil |

| artware | advertisement |