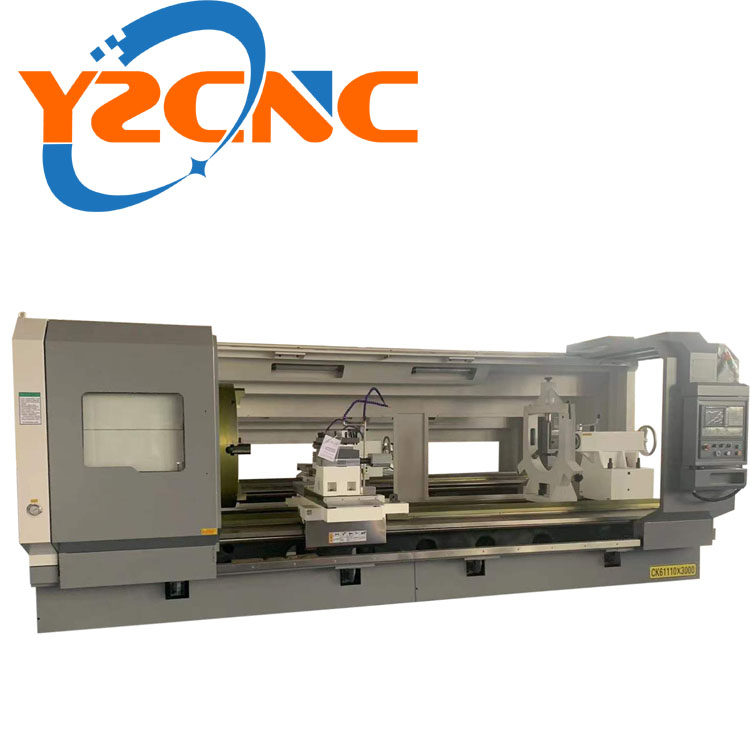

CK6140 Cnc Lathe machine All structures are designed, developed, and manufactured by the requirements of international standards. The whole machine has good precision and stability, muscular rigidity, small thermal deformation of the independent spindle, good precision retention, and excellent maintenance-free characteristics, suitable for heavy cutting. The machine concept has reached the advanced international level. Advanced structural design and perfect supply measures give the machine tool high reliability and long-term high precision retention.

CK6140 Cnc Lathe machine All structures are designed, developed, and manufactured by the requirements of international standards. The whole machine has good precision and stability, muscular rigidity, small thermal deformation of the independent spindle, good precision retention, and excellent maintenance-free characteristics, suitable for heavy cutting. The machine concept has reached the advanced international level. Advanced structural design and perfect supply measures give the machine tool high reliability and long-term high precision retention.

Ck6140 cnc lathe Processing workpiece range

Max. swing over bed:400mm

The working length of the workpiece be 750/1000/1500mm

Spindle Bore 52mm/60mm Larger spindle hole can be customized for 80mm On the premise of installing a 200mm manual chuck, it can pass a bar with a diameter of 50mm/58mm, When you buy a 6140 CNC lathe, if the workpiece needs to pass through the spindle hole, you need to communicate with the lathe manufacturer in advance

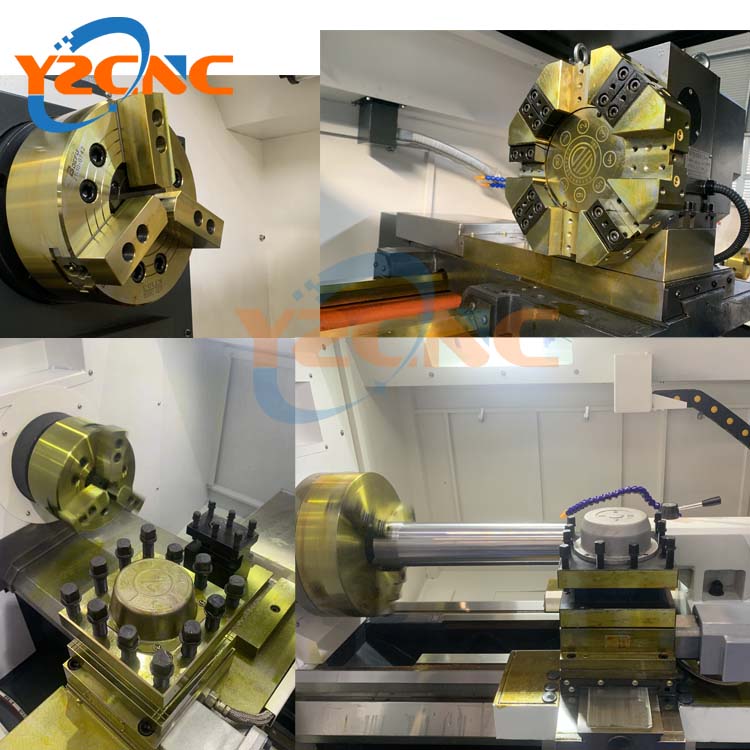

Ck6140 cnc lathe Chuck

Manual Chuck(2/3/4 jaw)

8inch/10inch 3-jaw Manual chuck, It is not recommended to choose a chuck larger than 8 inches on the 6140 lathe. A larger chuck spindle will bear greater weight during work, which will affect the life of the spindle, thereby reducing the use time of the lathe.

Hydraulic Chuck (hollow chuck and solid chuck)

Ck6140 cnc lathe Optional configuration hydraulic chuck (6/8inch). It should be noted that the hydraulic chuck has a difference between hollow and solid. The main components of the hydraulic chuck are the hydraulic station, the rotary cylinder, the chuck rod, and the chuck.

1. hollow chuck is through a hole in the center of the chuck, the workpiece can through chuck. When the hydraulic chuck is installed, the spindle hole will become smaller, For example, the spindle hole of CK6140 is 60mm. After the hydraulic chuck is installed, the diameter of the tie rod hole determines the diameter of the workpiece that can pass through. One pass will be around 48-52mm.

2. solid hydraulic chuck workpiece will not pass through the spindle bore. Compared with the hollow hydraulic chuck, the price of the solid hydraulic chuck is cheaper

Pneumatic Chuck (hollow chuck and solid chuck)

The advantages and disadvantages of pneumatic and hydraulic CNC lathe chucks are:

Advantages of pneumatic chuck: high clamping precision, long service life; no pollution, convenient and sensitive low-pressure adjustment, and less energy consumption.

Advantages of hydraulic pressure: large chuck clamping force, stable heavy cutting, clamping force up to 3.5MPa.

Disadvantages of pneumatic chuck: Pneumatic instability, easy to damage.

Disadvantages of hydraulic chucks: dirty, noisy, high energy consumption, low pressure difficult to adjust.

Hydraulic pressure is suitable for heavy loads, while pneumatics are suitable for light loads; hydraulic pressure has high requirements on oil, which is very delicate; the pneumatic medium is air, which is much better than hydraulic oil; the hydraulic system needs to be connected back to the oil pipe, and the pneumatic system discharges the gas directly into the atmosphere; Pneumatic noise is greater than hydraulic pressure, and another air source needs to be prepared, while hydraulic systems all have a hydraulic source; hydraulic pressure and pneumatic pressure can solve special problems in their respective fields according to the compressibility of their media.

Pneumatic is to use the compressibility of air. Air pressure is to use compressed air to exchange the cylinder stroke with high air pressure and sacrifice pressure. The air is compressed and stored, and the air has elasticity like a spring, and then controls its direction with the control element. , to drive the rotation and expansion of the actuator. The hydraulic pressure uses a large hydraulic oil stroke (hydraulic oil flow, driven by a hydraulic pump) in exchange for the thrust of the hydraulic cylinder.

Hydraulic pressure uses liquid as the working medium and uses the pressure energy of the liquid to transmit power. Pneumatic is to use compressed air as the power source to drive the machine to complete the expansion and contraction or rotation.

Ck6140 cnc lathe Cnc controller

GSK928TEA/GSK980TDi or KND

Siemens lathe is Simens808,Siemens828, Siemens840,Siemens

The SINUMERIK 808D is an economical operator panel-based CNC system. This compact and easy-to-use unit is suitable for basic turning and milling applications.

SINUMERIK 828D: The compact CNC for standardized machine structures

The SINUMERIK 828 CNC is ideally suited for standard machine tools produced in high volumes and with a low degree of modularity.

SINUMERIK 840 – the open CNC for modular machine structures

SINUMERIK 840D sl is extremely open and flexible. The SINUMERIK 840D sl is the ideal CNC system for machine tools whose mechanical configuration needs to be adapted to specific user needs.

Fanuc lathes

FANUC system is a common CNC machine tool program in CNC machine tool workshops, and its operation panel is simple and easy to understand.

Syntec lathe is syntec6ta

KND Lathe

K100T-C(i) universal lathe CNC system plays a connecting role in the lathe products of Kanende Company and is the replacement product of the original K100T system. A number of new functions have been added to the system software to meet the basic needs of users. In terms of hardware, it adheres to the consistent high reliability of the KND system, has low requirements on the surrounding environment, can adapt to harsh environments, and is suitable for economical lathes.

GSK 980TDi is a new member of the GSK 980TD series product family. It is built by the original team who have successfully developed GSK 980TD, GSK 980TDa, GSK 980TDb, GSK 980TDc, and other product project teams. The latest masterpiece in the CNC lathe and turning center market.

GSK 980TDi is a new member of the GSK 980TD series product family. It is built by the original team who have successfully developed GSK 980TD, GSK 980TDa, GSK 980TDb, GSK 980TDc, and other product project teams. The latest masterpiece in the CNC lathe and turning center market.

GSK 980TDi is based on the GSK-Link industrial field bus and is equipped with a bus-type servo drive unit and a servo motor with a multi-turn 23-bit absolute encoder as standard, realizing 1nm-level position accuracy, the online configuration of servo parameters and mechanical zero return without gear blocks. At the same time, it invites well-known experts in the field of industrial design to carry out a new design of the appearance structure, which is refreshing. In addition, the project team has carried out a lot of research work on efficiency improvement, intelligent application, humanized operation, and user secondary development.

GSK 928TEa lathe CNC system adopts a 32-bit high-performance industrial-grade CPU and ultra-large-scale programmable gate array integrated circuit chip CPLD to form the control core to realize μm-level precision motion control. The system has strong functions, stable performance, an intuitive and concise interface display, and easy operation. It can be used in conjunction with the AC servo drive (drive unit, servo motor) independently developed and manufactured by Guangzhou CNC Equipment Co., Ltd. Through programming, the processing of outer circle, end face, grooving, taper, arc, thread, etc. can be completed, which has a high performance-price ratio

Independent spindle and two gears(CK6140A and CK6140F)

1.CK6140A is an Independent spindle The advantage of the independent spindle lies in its simple structure and wide speed range, which can meet the processing requirements of high speed and high precision. At the same time, since the speed of the independent spindle is directly driven by the motor, its response speed is fast, and the processing parameters can be adjusted quickly. In addition, the maintenance cost of the independent spindle is relatively low because of its simple structure and easy repair.

2.CK6140F Gearbox lathes two gears advantage of the gearbox is that it has a large torque output, which can meet the processing requirements of heavy cutting and heavy load. At the same time, the structure of the gearbox is stable, which can ensure machining accuracy. In addition, the processing noise of the gearbox is relatively low, which will not cause too much disturbance to the working environment.

To sum up, independent spindles and gearboxes have their advantages and disadvantages, and they need to be selected according to specific processing requirements and workpiece characteristics. If you need high-speed and high-precision machining, you can choose an independent spindle; if you need heavy cutting and heavy-duty machining, you can choose a gearbox.

Ck6140 cnc lathe Tailstock

Manual /Hydraulic/pneumatic manual.

MT4, Travel 140mm

Ck6140 cnc lathe Motor

Motor (Spindle motor, X/Z Motor)

1. Spindle can choose a servo motor and Inverter motor, Spindle motor

2.X/Z Motor is a servo motor, The same brand as the CNC system. This is very important. When purchasing a CNC lathe, you must agree with the lathe manufacturer to include it in the contract.

Ck6140 cnc lathe Automatic Turret

Four-station electric turret is a Vertical Tool shank type 20*20mm

A six/eight-station electric turret is a horizontal Tool shank type 20*20mm

Eight Hydraulic servo turret

Ck6140 cnc lathe Other optional configuration

1. Automatic Oil bath feeder

Max. dia 42mm, Max. length 3000mm

2. Square cutting power head and Milling’s head

Ck6140 cnc lathe working accuracy

| Working accuracy | Positioning accuracy | MM | X≤0.010 Z ≤0.015 |

| Repeatability Positioning accuracy | MM | X≤0.0075 Z ≤0.010 | |

| Min. unit set | MM | 0.001 | |

| roundness | MM | ≤0.007 | |

| Diameter uniformity | MM | ≤0.03 (length 300) | |

| Flatness | MM | ≤0.02 (Diameter 300) | |

| Surface Roughness (Steel) | Ra1.6um | ||

Cnc lathe machine have CK6136,CK6140,CK6150,CK6163,CK6180,CK61100,CK6125