First needs one Wheel Straightening Machine is used for internal and external deformation, twists and turns, roundness, dentation, etc. The wheel correction machine is controlled by a simple hydraulic unit. It can position the damaged part and combines thermal treatment and an artificial aging process. It does not destroy the molecular structure and mechanical properties of the alloy wheel. It can quickly restore the wheels to their original state.

First needs one Wheel Straightening Machine is used for internal and external deformation, twists and turns, roundness, dentation, etc. The wheel correction machine is controlled by a simple hydraulic unit. It can position the damaged part and combines thermal treatment and an artificial aging process. It does not destroy the molecular structure and mechanical properties of the alloy wheel. It can quickly restore the wheels to their original state.

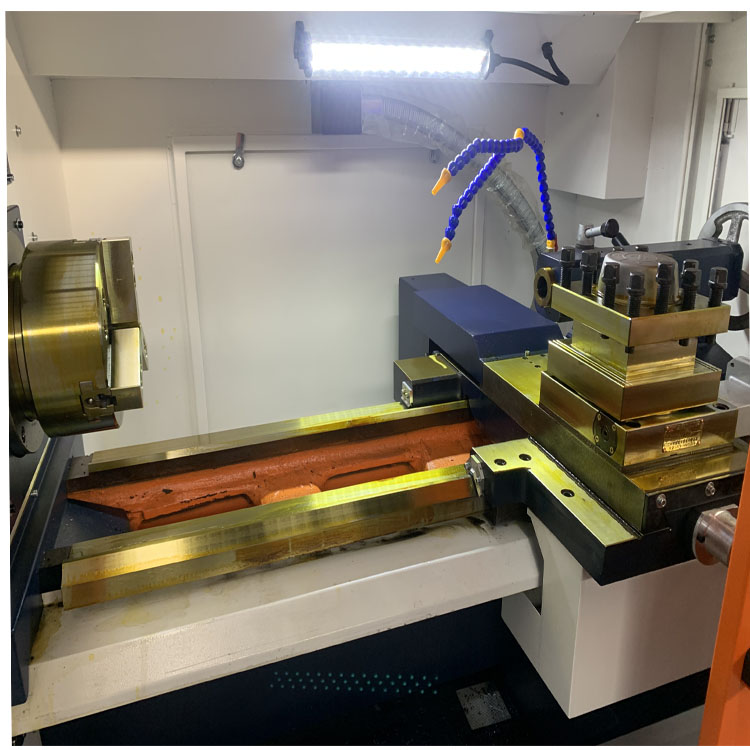

Wheel CNC Lathe equipment:

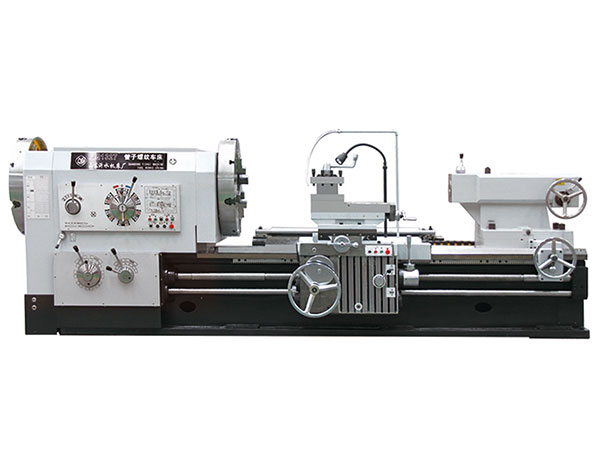

alloy wheels need to be operated on lathe equipment for surface treatment, grinding, and balance calibration. The rotating equipment can be specialized machines or general-purpose lathes, grinders, and other mechanical equipment.

Grinding machine:

A grinding machine is used for the surface treatment of alloy wheels, such as rust removal, oxidation removal, and cleaning. At the same time, the grinding machine can also be used for grinding and polishing the wheels.

Oven:

Before applying a new coating, the alloy rim needs to be thoroughly cleaned and dried. An oven can be used for drying the wheels to ensure that the surface is dry and free of oil stains.

Spray equipment:

Special coatings and spray equipment are needed for coating refurbishment. The spray equipment can be a spray gun or a paint sprayer, and the coating needs to be carefully blended and sprayed to achieve the best surface coating for Lv alloy wheels.

Balance calibration equipment:

If alloy wheels are unbalanced during use, it can cause vibration and swaying, and even damage the wheels or cause other dangers. Therefore, balance calibration needs to be performed before applying a new coating. The balance calibration equipment can help workers find the location of the imbalance and provide corresponding adjustment solutions.

Refurbishing wheels is an important process that involves several steps to ensure that the wheel is safe and functional. In this article, we will discuss the steps involved in refurbishing wheels.

Inspection

The first step in refurbishing a wheel is to inspect it thoroughly. This is done to determine the extent of the damage and the repairs needed. During the inspection, the technician will look for cracks, bends, corrosion, and other damage that may have occurred.

Cleaning

The second step is to clean the wheel. This is done to remove any dirt, debris, or brake dust that may have accumulated on the wheel. The cleaning process may involve using a wire brush, a pressure washer, or a chemical cleaner.

Stripping

The third step is to strip the wheel of any existing paint, coating, or finish. This is done to prepare the surface for repairs or repainting. The stripping process may involve using a chemical stripper or sandblasting.

Repairing

The fourth step is to repair any damage that was found during the inspection. This may involve welding, straightening, or sanding down any rough edges. The goal is to restore the wheel to its original shape and form.

Sanding

The fifth step is to sand the wheel to remove any imperfections or rough spots. Sanding is done to create a smooth and even surface that will allow the new finish to adhere properly.

Painting

The sixth step is to paint the wheel. This is done to protect the wheel from corrosion and to give it a new look. The painting process may involve using a primer, base coat, and clear coat to achieve the desired finish.

Curing

The seventh step is to cure the paint. This is done to ensure that the paint has properly adhered to the surface of the wheel. Curing may involve baking the wheel in an oven or allowing it to air dry for a specific amount of time.

Balancing

The eighth and final step is to balance the wheel. This is done to ensure that the wheel is properly balanced and that it will not cause any vibrations while driving. Balancing is done by adding weights to the wheel at specific locations to achieve the desired balance.

In conclusion

refurbishing wheels is a process that involves several steps. Each step is important and must be done correctly to ensure that the wheel is safe and functional. By following these steps, technicians can successfully refurbish wheels and give them a new lease on life.

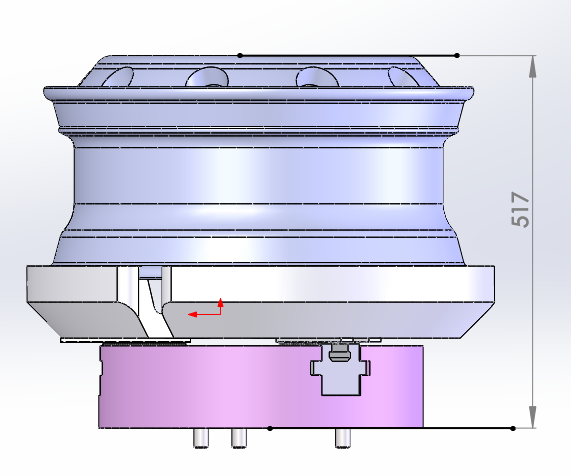

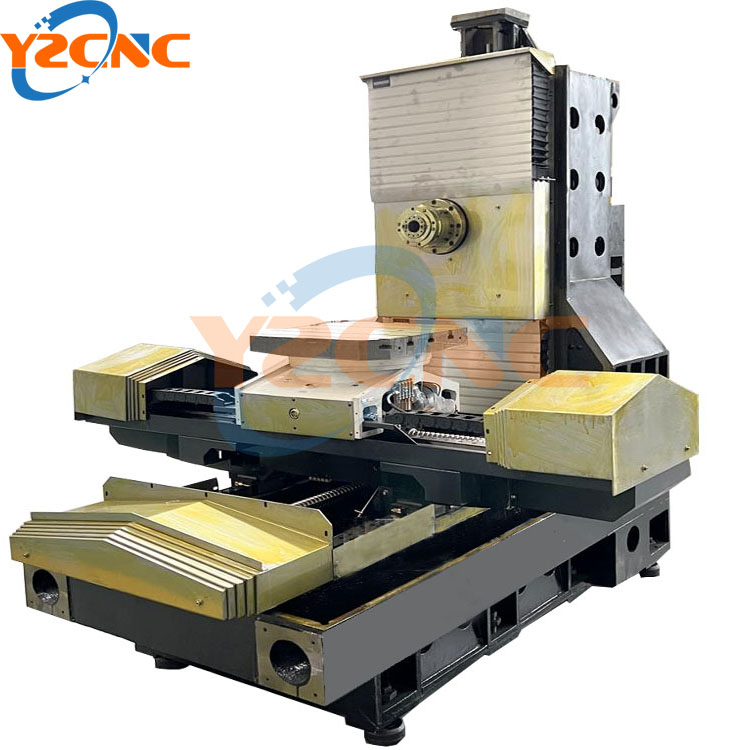

YZCNC Alloy Wheel Machine

WhA wheel straightening machine is specifically used to repair the twist, deformation, and depression of various types of aluminum alloy wheels. It has the advantages of unique design schemes, standard plastic effects, and sample operation processes. This device uses a simple operation of a mobile piston system, which is controlled by the hydraulic unit. In the case of molecular structure and mechanical properties that do not destroy its aluminum alloy, the damaged wheels are located, and the heat treatment and labor time effect can be quickly restored to the original state. The device is equipped with a complete set of core tools and components. Yuzhuo Machinery (YZCNC) alloy wheel repair machine also has the characteristics of non-polar transmission (0-300R/min), and can also perform a variety of functions such as bias detection, positioning mark, plastic surgery, lathe cutting, surface polishing, etc. The world’s momostdvanced aluminum alloy wheel repair equipment.

The wheels are also called steel rings. They are important parts of the middle cylindrical part of the tire in the wheels to support the entire car and ensure that the car can drive safely.

Once the wheels are deformed, the harm to the car is relatively large, and the deformation of the wheel may cause the car to shake during driving, or the jitter occurs when driving at high speed. There may also be a phenomenon of slow leakage of the wheels. Once such situations occur, it is necessary to detect them in time and conduct professional maintenance and plastic surgery for problems that occur.

The deformation of the hub is a common situation of the damage of the hub. The cause of the deformation is usually accidentally hitting the wall or railing during driving. It may also be a stone that can be avoided. It is very likely to hit the wheels to deformation.

Yuzhuo Machinery (YZCNC) Automobile Insurance Equipment Factory has independently developed the WRC Rim repair cnc lathe machine series aluminum alloy steel ring repair machine after years of careful research. It fills the domestic gap and has been repeatedly rated as the top ten brands of maintenance equipment. The device includes three parts: dynamic balance detection, mechanical processing, and hydraulic plastic surgery. It repairs a variety of types of automotive aluminum alloy wheels without destroying the molecular structure and mechanical properties of aluminum alloy. The device was exported to the United States, Australia, Hungary, Russia, the Middle East, and other countries, and was praised by users from various countries. Products are also constantly updating, and strive to do better in this field.